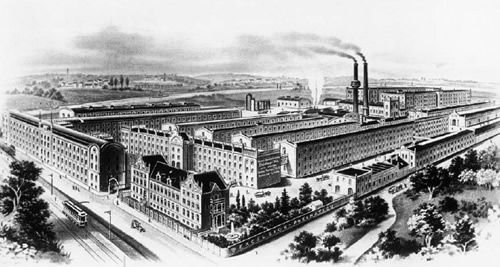

Continental built a plant on the site in Seelze for the production of regenerated material, i.e. for the reprocessing and recycling of used rubber

Visit Continental Tires in your country for local vehicle fitment

#Sustainability #History

Sustainability has History with Us

120 Years of Circular Economy at Continental

At Continental, we are convinced that sustainable and responsible business practices increase our ability to innovate and the future, thus creating corporate value. Our ambition is clear: by 2050 at the latest, we want to work with our partners to completely close our product and resource cycles – and make circular economy a reality.

For us, sustainability doesn't just start now. For example, we have been active in the retreading of truck and bus tyres for more than 120 years!

Wie alles begann

In order to conserve resources and reduce costs, Continental planned to purchase a new factory site as early as 1899, where a regenerated factory for the processing of used rubber was to be put into operation. At the same time, a solution was developed for the ever-increasing volume of used tires. In 1903, exactly 120 years ago, the plant was put into operation.

But even before 1903, Continental was already engaged in retreading. First at the Hanover-Vaherenwald plant, later also at other locations in Germany or abroad.

Good2know

According to a study by the Fraunhofer Institute for Environmental, Safety and Energy Technology (UMSICHT), retreaded tires now save up to 50 percent CO2 emissions compared to new tires. The proportion of recycled and renewable materials in retreaded tires is up to 85 percent. They are in no way inferior to new tyres in terms of traction, grip and safety.

Since it also seemed desirable to us to separate some of the secondary branches of our production from the main plant, we acquired a larger area in the neighboring Seelze [...].

Excerpt from the Annual Report 1899

1903

1929

After a fire on the factory premises, the regeneration plant in Seelze was closed. The activities were completely transferred to the Limmer plant.

The foundation was laid

At that time, 100 employees were already processing 9-13 tons of waste rubber every day. This is roughly equivalent to the weight of 185 truck tires or around eight passenger cars.

In this way, Continental laid the foundation for sustainable and circular business 120 years ago.

And how does retreading work?

Tires consist of a carcass and a tread. Even if the tread is worn out, the carcass is usually still completely intact. During retreading, the remaining tread rubber is roughened and replaced, as is the case with hot retreading also the sidewall of the tire. In this way, the carcass is prepared for a second and third tire life. Continental uses state-of-the-art analytical methods, manufacturing methods and recycling technologies in hot and cold retreading. In both methods, only carefully selected and properly tested carcasses are used. As a rule, around 70 percent of the material of the original tire can be reused in both hot and cold retreading.

What happend next?

Other Milestones

1980

Closure of the regenerated factory in Limmer

1992

Founding of his own recycling company: Tire Disposal Company (REG). The primary goals of the foundation were to establish and ensure environmentally friendly tire disposal in Germany.

With this measure, Continental was the first tire manufacturer in Germany to assume responsibility for the disposal of its products.

2013

With the opening of the ContiLifeCycle plant in Hanover Stöcken, Continental has combined a retreading plant and a recycling plant.

Further information can be found here: ContiLifeCycle

And what does the future hold?

We work every day to advance innovative technologies and sustainable solutions along the entire value chain – from sourcing sustainable materials to recycling end-of-life tires. For example, we also rely on the pyrolysis of used tires. Our overarching goal is to recover 60 percent of the materials used in tire construction from end-of-life tires by 2050 at the latest.

The most sustainable tire in series production

With the UltraContact NXT, we have brought the most sustainable tire to date into series production. Up to 65% sustainable materials are used in the tires.

Conserving resources

Since 2020, we have been sourcing 100 percent of our electricity from renewable energies at our production sites worldwide. By 2040, our production should be climate-neutral.

Circular Economy

Since September 2023, thanks to pyrolysis, we have been able to use recycled industrial soot for our production of solid tires

More related content on this topic

Press Release

Focus on the Circular Economy: Continental Celebrates more than 120 Years of Retreading for Truck and Bus Tires

Sustainable Materials in Tire Production