# Future mobility

Rolling into a sustainable future

Sustainable solutions for future success

We keep the future in motion, but in which direction is the future of mobility headed? How are we directing the momentum through our actions today? Our Tyres Vision 2030 strategy answers these questions. It leads the way for our journey towards sustainable mobility, as the most progressive tyre manufacturer in terms of environmental and social responsibility. Here’s how…

Innovative products and technologies to help tackle climate change

The tyre imprint of our organisation is large. Almost every third car in Europe is delivered with our tyres. And with every set, our responsibility for people and the planet grows. The topic of sustainable transportation is not only high on our agenda right now, it is deeply anchored in the foundation of our values.

We are convinced that sustainable and responsible business increases our ability to innovate and be prepared for the future and that it is our task to stay ahead of the technology to contribute to a decarbonised tomorrow.

Climate change and greenhouse gas emissions have become central challenges for companies, governments and society – in short, for all of us. We are renowned for bold innovations and ambitious goals and our ambitions in the field of clean and safe mobility solutions are no exception. That is why we strive to be the most progressive tyre manufacturer in terms of environmental and social responsibility.

We want to tackle climate change – by operating with energy-efficiency and by developing products that help reduce CO₂ emissions. We aim to use increasingly scarce raw materials as efficiently as possible and to develop sustainable alternatives. For increased energy efficiency, greener production, use and recyclability, we are systematically investing in the research and development of new technologies, innovative materials and smart production processes.

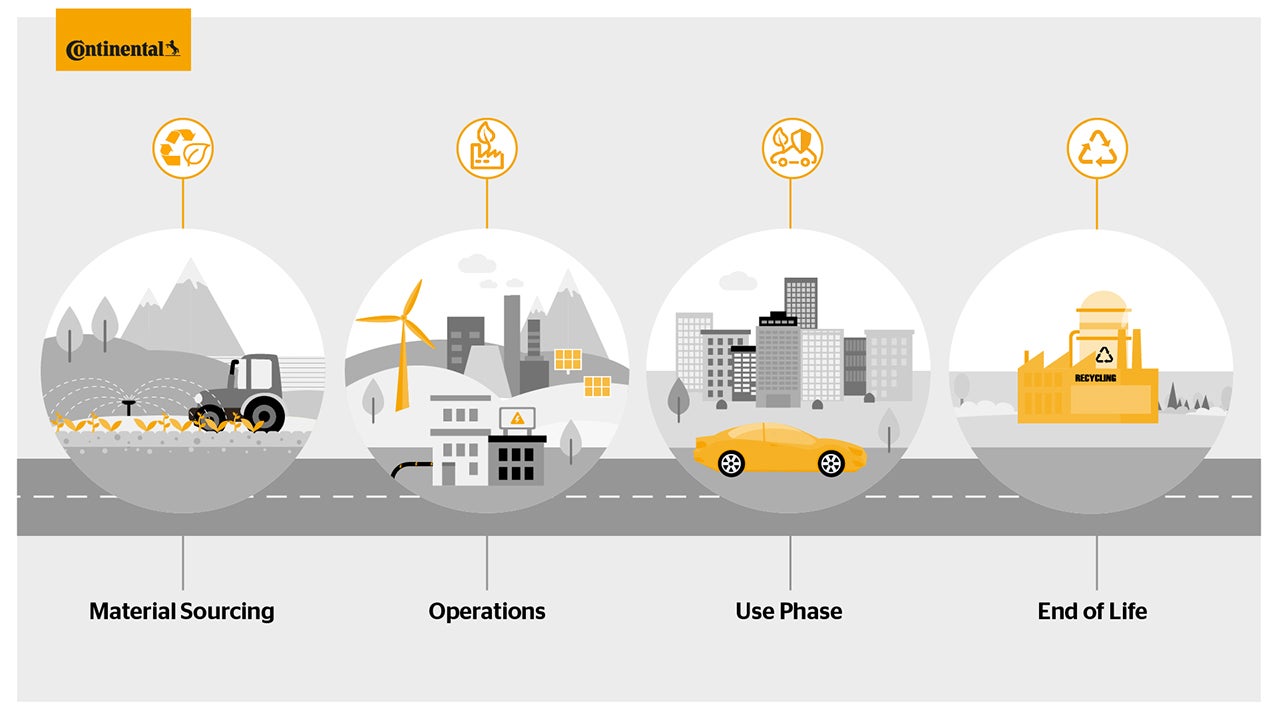

To continue challenging ourselves and keep improving in terms of sustainability, we have divided our efforts into eight strategic fields. These are each assigned to four phases of the value chain (see info box). Sustainability is firmly integrated in our corporate strategy and is a key driver of innovation along every step of the way.

What is the value chain?

A value chain is a business model that describes the full range of activities needed to create a product or service. For companies like ours that produce goods, that means all steps to design, produce, market, deliver and support a product. By understanding how processes are linked, we can improve our sustainability, for example by increasing production efficiency to deliver maximum value with the least possible impact.

How clean sustainable solutions reduce emissions all along the value chain

Material Sourcing: sustainable materials and supply chain

In this phase of the value chain, our main challenge is to source materials fairly and sustainably. On the one hand, we want sustainable materials in our products; on the other hand, we want them to be responsibly sourced. Due to global trade, value chains can consist of a high number of links, so they quickly become complex.

As a manufacturing company, we are rising to this challenge by investing in research and development, new technologies, alternative materials and environmentally compatible production processes. Through these efforts, we are aiming for a gradual transition to 100% sustainably produced materials in our tyres by 2050 at the latest. We define all materials as sustainable that originate from a closed material cycle, have no harmful impact on humans or the environment, are procured responsibly and are carbon neutral along the entire supply chain.

For example, we are taking responsibility with a project to ensure full traceability of the natural rubber supply chain in the Indonesian province of West Kalimantan in Borneo, which meets sustainability criteria and increases the income of local smallholders. At the same time, we are developing innovative materials like natural rubber from dandelions in our Taraxagum research project.

Operations: energy and resource-efficient, low-emission production

Once we have the materials, we need energy to transform them into tyres. That is why we want to establish highly resource and energy-efficient operations that produce the lowest emissions possible. We have continuously been increasing our efficiency in water and energy consumption for more than a decade.

In fact, we are already consume 55% less water and 17% less energy than the industry average per metric ton of tyres produced. By 2030, our strategy is to increase those savings by an additional 20%. All electricity purchased for our production sites has been switched to renewable energy and is already carbon-neutral.

Use Phase: safe, energy-efficient and long-lasting products

We are known for safe, energy-efficient and long-lasting tyres. Our research and development department is continually changing, updating and improving our products. Our goal is to continuously improve their mileage, wear rate and rolling resistance. Our rolling resistance optimised tyres are already contributing to this goal today.

Thanks to reduced rolling resistance, they require less fuel or energy, so they save CO2 or extend the range of a vehicle whenever they are used. By equipping tyres with sensors that monitor tyre pressure and tyre temperature, we further help keep rolling resistance at an optimal level to reduce emissions and extend the range of electric vehicles.

Each new development is an important step on our way to becoming a carbon neutral business contributing to emission-free mobility.

End of use: renewed and recycled tyres

Natural rubber is a precious resource. Even the most durable tyres become worn down eventually, but that doesn’t have to be the end of their journey. They are a valuable source of material. Our unique recycling technologies enable the return of rubber from worn tyres to the production process for new tyres and retreads.

ContiLifeCycle™ is a successful example of what we can already achieve today. Our truck tyre plant in Hanover-Stöcken, Germany, is a production facility that unites tyre recycling and retreading under one roof, thus setting new benchmarks in sustainability. The retreaded tyres save up to 24% CO₂ emissions, land use and air pollution, while reducing the use of material by 70% and water consumption by 19%. Our goal is to expand recycling to include all tyres and produce 100% renewed and recycled tyres by 2050.

*Source: Ernst & Young et Associés, 2016

Our journey to be the most progressive tyre company in terms of environmental and social responsability

We are constantly increasing the sustainability of our production processes and products – in line with our global sustainability strategy. These are the next steps on our journey

2022

- Carbon-neutral business for zero exhaust emission vehicles

2025

- 0% coal and fuel oil usage for onsite steam production

- VECTO: Trendsetting product roadmap for truck tyres

2030

- 60% sustainable materials in flagship products

- 20% waste reduction; 95% waste recycling rate

- 20% energy and water reduction

2040

- 100% decarbonised production

2050

- 100% sustainable materials

- 100% carbon-neutral supply chain

- 100% renewing and recycling of our tyres