Continental built a regeneration factory in Seelze to reprocess and recycle used rubber.

#Sustainability #History

Circularity Is Part of Our History

120 years of resource conservation at Continental

We firmly believe that closed material cycles increase our ability to innovate and ensure our long-term viability – creating value for the company. Our goal is clear: by 2030, we aim to increase the share of recycled and renewable production materials used in our tires to at least 40 percent. This is an important step toward a truly circular material economy.

Learn more about our sustainability strategy here.

Sustainability is not new to us. For more than 120 years, we have been retreading truck and bus tires. Retreading involves reusing the carcass of a worn tire – which saves valuable resources.

From the regeneration factory to the ContiLifeCycle plant

Back in 1899, we began planning a new site for a regeneration factory to process used rubber. Even then, our ambition was clear: to conserve resources, reduce costs and provide a solution for the growing number of end-of-life tires.

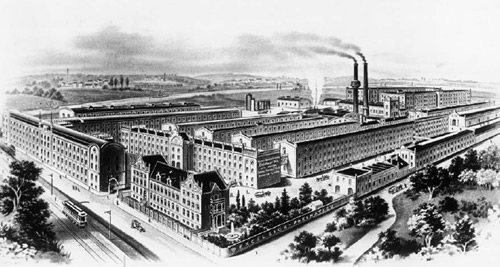

In 1903, the plant was put into operation, marking a milestone in our company’s history and an early step toward a circular economy. But our commitment to reusing tires began even earlier. Before 1903, we had already started retreading tires – first at our Hanover-Vahrenwald plant and later also at other locations in Germany and around the world. This approach extended tire life and reduced waste – principles that remain central to our sustainability strategy today.

Good2know

A study by the Fraunhofer Institute for Environmental, Safety and Energy Technology (UMSICHT) shows that, with identical rolling resistance (Class C) and comparable mileage, retreaded tires generate over 60 percent fewer CO2 emissions during production than equivalent new premium tires. They also require about two-thirds fewer raw materials, conserving valuable natural resources – especially rubber. As a result, retreaded car tires have a lower overall carbon footprint than comparable new tires, based on mileages of 20,000 km/40,000 km).

Source: Ecological assessment of retreading – final report, Fraunhofer Institute for Environmental, Safety and Energy Technology (UMSICHT) (published on July 6, 2022)

Since it also seemed desirable to us to separate some of the secondary branches of our production from the main plant, we acquired a larger area in the neighboring Seelze [...].

Excerpt from the Annual Report 1899

1903

1929

After a fire on the premises, the regeneration factory in Seelze was closed and all operations were moved to the Limmer plant.

Laying the foundation

At that time, 100 employees were already processing 9 to 13 tons of waste rubber every day. This is roughly equivalent to the weight of 185 truck tires or around eight passenger cars.

Continental thus laid the foundation for a circular economy 120 years ago.

How does retreading work?

Tires consist of a carcass and a tread. Even when the tread is worn down, the carcass is usually still completely intact. During retreading, the remaining tread rubber – and in the case of hot retreading, the sidewall as well – is buffed and renewed. This prepares the carcass for a second or even third tire life. Continental uses state-of-the-art analysis techniques, manufacturing methods and recycling technologies for hot and cold retreading. In both processes, only carefully selected and thoroughly inspected carcasses are used.

What happend next?

Further Milestones

1980

Closure of the regeneration factory in Limmer

1992

Founding of our own recycling company: Reifenentsorgungsgesellschaft (REG). The primary goal was to establish and ensure environmentally responsible tire disposal in Germany.

With this step, Continental became one of the first tire manufacturers in Germany to take responsibility for the disposal of its products.

2013

With the opening of the ContiLifeCycle plant in Hanover-Stöcken, Continental combined a retreading facility with a recycling plant.

Learn more here:ContiLifeCycle

What does the future hold?

Every day, we work to advance innovative technologies and solutions along the value chain – from sourcing renewable and recycled materials to recycling end-of-life tires. Retreading truck and bus tires remains a key component of this effort.

Furthermore, we use highly efficient processes such as pyrolysis to recover valuable materials from end-of-life tires and reintroduce them into the production cycle.

This way, we combine proven approaches with modern technologies to actively shape the transition to closed material cycles.

High share of recycled and renewable materials in production tires

With the UltraContact NXT, we launched our first tire comprising up to 65 percent renewable, recycled and ISCC PLUS mass-balance-certified materials.

Conserving resources with renewable energy

We are increasingly generating our own renewable energy, for example by expanding photovoltaic systems at our production sites worldwide. Since the end of 2020, all externally sourced electricity for our global tire plants has come from renewable sources. Compliance is verified through energy attribute certificates in line with the RE100 initiative.

Recycled carbon black for our forklift truck tires

Since September 2023, thanks to pyrolysis, we have been using recycled industrial carbon black in the production of our forklift tires.

More related content on this topic

Press Release

Focus on the Circular Economy: Continental Celebrates more than 120 Years of Retreading for Truck and Bus Tires

Sustainable Materials in Tire Production