Activities and Initiatives

Operations

To make tire production even more environmentally friendly in the future, Continental is investing in energy-efficient, resource-efficient and low-emission production processes.

We are working systematically toward:

- Phasing out the use of coal and fuel oil for steam generation at our tire production sites worldwide

- Continuously reducing our environmental impact in the areas of energy, water and waste recovery

- Achieving low-carbon tire production

Energy Efficient, Resource Efficient, Environmentally Friendly

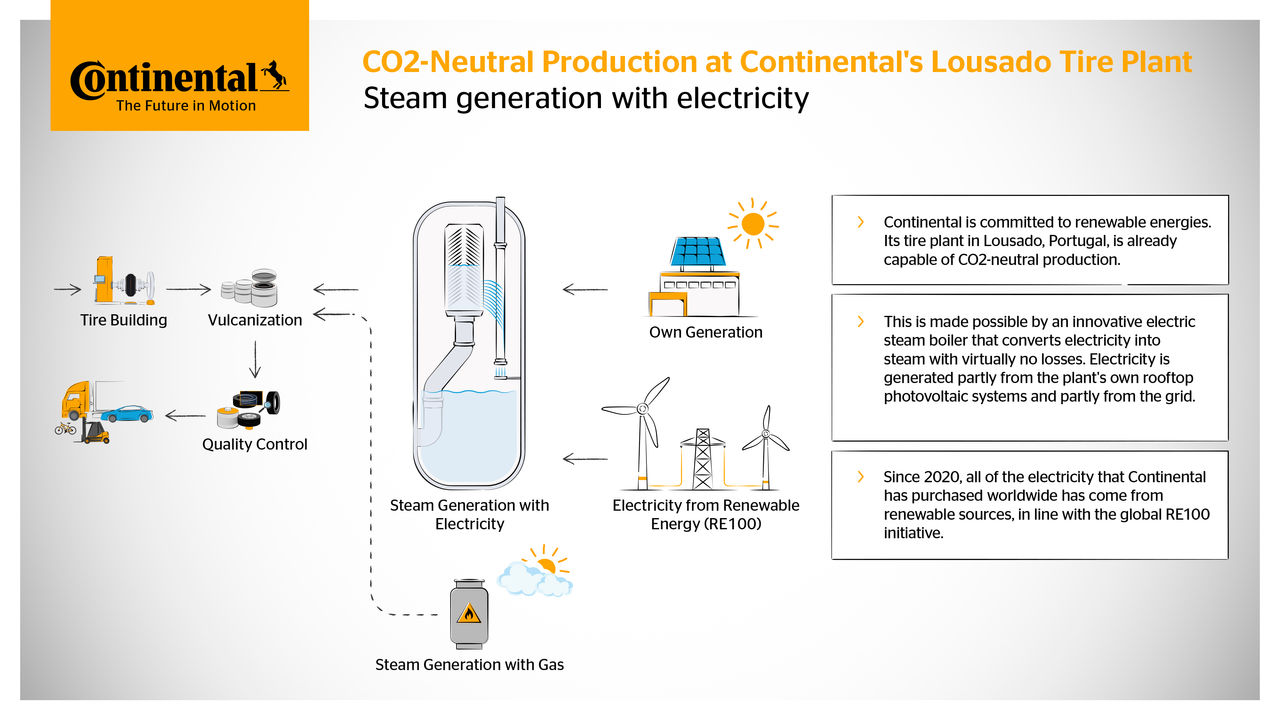

Energy plays a vital role in tire manufacturing – for example, in generating steam for tire vulcanization. That’s why we are increasingly producing renewable energy ourselves by expanding photovoltaic systems at our production plants worldwide, for example.

Since late 2020, all the electricity purchased for our tire production facilities worldwide has been carbon-neutral and derived from renewable sources. To verify this, we secure energy attribute certificates in accordance with the criteria of the RE100 initiative.

At the same time, we have implemented a wide range of measures to make our operations even more energy efficient. In 2024 alone, we reduced our energy use by around 50 gigawatt hours through more than 80 energy-saving projects worldwide – roughly equivalent to the annual energy consumption of over 4,000 single-family homes in Germany. Combined with our efforts in 2023, we achieved a total reduction of 200 gigawatt hours within two years.

Using water efficiently – a key lever for more sustainable tire production

Water is an essential resource in tire manufacturing – used for heating, cooling, and cleaning. That’s why we focus on technologies and processes that reduce consumption and increase reuse. From 2020 to 2024, we already reduced our water withdrawal per ton of product by more than 10 percent.

This progress is supported by risk assessments and water audits, especially in regions facing higher water stress. Advanced filtration and membrane technologies – some with 3D-printed pores – already enable the reuse of 90 percent of treated wastewater.

We also optimize our production processes for efficiency: cooling water and steam are reused multiple times, online leakage detection systems prevent unnecessary losses, and steam condensate is recovered. Switching to reverse osmosis and replacing inefficient filters further improves water treatment in our plants.

In Lousado, we are showing that even very large tire plants can produce CO2-neutrally.

Since 2024, we have been able to produce tires in a CO2-neutral manner at our tire plant in Lousado, Portugal. This is made possible by the generation of steam with the help of a boiler that is operated purely electrically. We use both self-generated solar power and renewable electricity from the power grid to generate steam.

"In Lousado, we are showing that even very large tire plants can produce CO2-neutrally. The availability of renewable energy sources at competitive prices is crucial for this," explained Dr. Bernhard Trilken, Head of Production and Logistics at Continental Tires.

He added: "We are preparing our plants to be able to use as much renewable energy as possible. The commissioning of our electric steam boiler in Lousado is the beginning of an exciting learning curve."

The electric boiler can generate steam from green electricity instead of gas

The electric boiler can generate steam from green electricity instead of gas

Other Activities and Initiatives

-

2026/01/21We strongly believe that the circular economy is the future. This is why we are developing innovative methods to enable material to be recovered, recycled and re-used.Post-UseRead more

2026/01/21We strongly believe that the circular economy is the future. This is why we are developing innovative methods to enable material to be recovered, recycled and re-used.Post-UseRead more -

2026/01/21Our tire supply chain is 100 percent carbon neutral by 2050 at the latest. Find out what we are doing to achieve this goal.Design & SourcingRead more

2026/01/21Our tire supply chain is 100 percent carbon neutral by 2050 at the latest. Find out what we are doing to achieve this goal.Design & SourcingRead more -

2026/01/21We supply durable, energy-efficient tires that offer the very best safety characteristics.Product UseRead more

2026/01/21We supply durable, energy-efficient tires that offer the very best safety characteristics.Product UseRead more