Tire and Road Wear Particles

Tire wear is an unavoidable result of friction between tires and the road. Friction is crucial for road safety, as it provides the necessary grip for safe braking and driving. In the sections below, we explain more about this process and how Continental is using innovative technologies to maximize grip and minimize wear.

What is tire abrasion and why is it necessary?

When a vehicle is driven, friction and the transfer of force between the tire and the road cause particles to be released from both the tire tread and the road surface. These are known as tire and road wear particles (TRWP).

This abrasion is a natural and unavoidable part of driving. The friction that causes it is what enables a car to accelerate, brake and corner safely and in a controlled manner. Without friction, vehicles would not be able to grip the road. This is why friction is essential for road safety.

What are tire and road wear particles?

According to the United Nations Environment Programme (UNEP), tire and road wear particles (TRWP) are classified as secondary microplastics. These particles are a mixture of rubber, road surface material and mineral components. Because of this composition, they differ significantly from most other forms of microplastics in terms of their structure, behavior and environmental impact.

Studies from the Tire Industry Project (TIP) show that TRWP typically consist of tire tread material combined with fragments from the road surface, along with other particles such as sand and road dust.

These elongated wear particles are denser than water (1.8 g/cm³) and average 100 µm in size – roughly the diameter of a human hair.

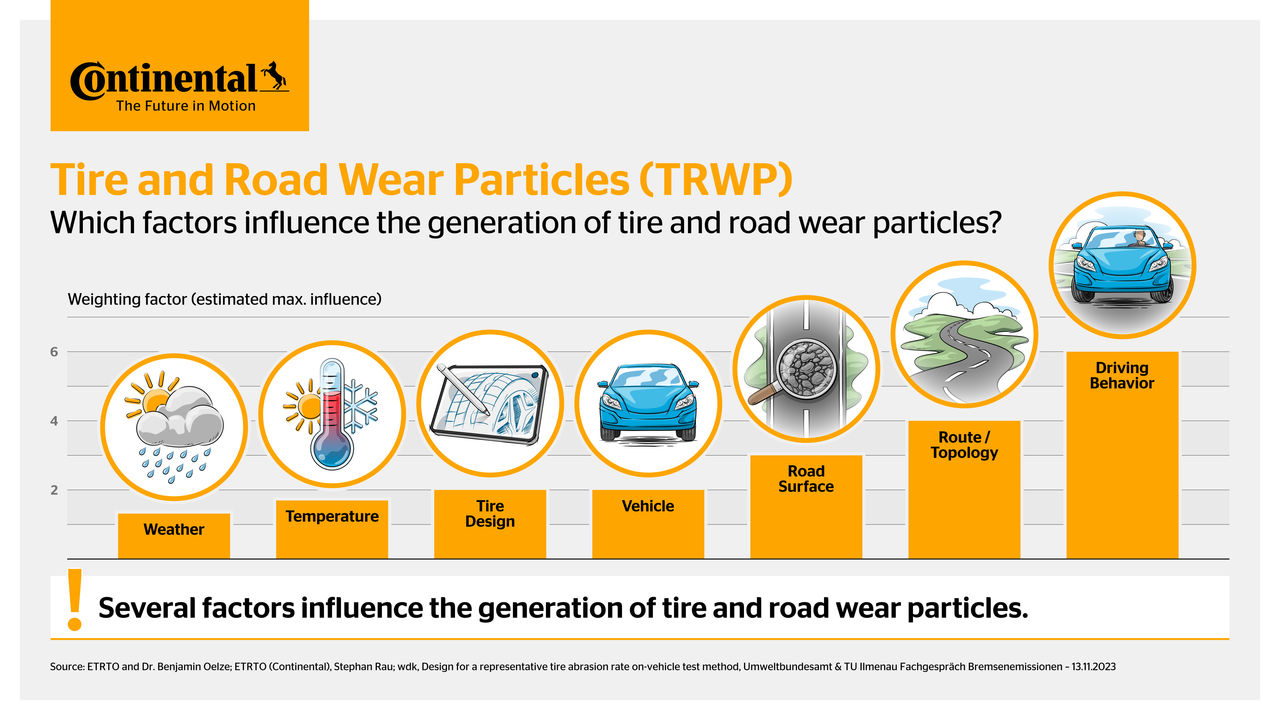

What factors influence tire and road wear particles?

The amount of tire and road wear particles released into the environment depends on many factors.

Some factors that influence tire and road wear can be controlled, such as a person’s driving style:

Driving style: Driving fast, braking hard and accelerating quickly all increase tire abrasion. Smooth acceleration and gentle braking, on the other hand, can prevent unnecessary tire abrasion and extend tire life.

Vehicle: Heavier vehicles and cars with sport-tuned suspension and wheel alignment tend to wear out tires faster. Lightening a vehicle’s load can help reduce abrasion and make tires last longer. If your car is heavier than usual, for example when going on vacation, adjust the tire pressure and check it regularly. Tires can wear out faster if the pressure is too low or too high. Irregular wear may also point to issues with the axle alignment, which should be checked and corrected by a specialist.

Road surface and infrastructure: Concrete is harder on tires than asphalt, and potholes can increase abrasion too. Winding mountain roads and stop-and-go traffic in cities also put constant stress on the tires.

Weather conditions: Wet roads and extreme temperatures can influence tire abrasion, so it’s important to choose tires that fit the conditions.

Studies show that driving style, road surface and road design have a much greater influence on tire and road wear than tire design. In fact, driving style affects tire abrasion three times more than tire design.

Where do tire and road wear particles end up in the environment?

Tire and road wear particles (TRWP) can enter the environment through various emission pathways:

Continental participates in numerous research projects to better understand these pathways and further reduce tire abrasion.

What is Continental doing to reduce tire and road wear particles?

Continental continues to make its tires more sustainable and environmentally friendly. In 2024 alone, the company invested €349 million in research and development in its Tires group sector.

To gain a comprehensive understanding of the many aspects of tire and road wear particles, Continental is actively involved in industry associations as well as several internal projects and research collaborations, including for example:

Co-chair and founding member of the Tire Industry Projects (TIP), an initiative that promotes research on the potential environmental impacts of tires throughout their entire life cycle.

Research collaboration with the University of Braunschweig, Germany. Continental engineers develop innovative tire designs and materials to reduce wear without compromising safety or performance.

Verbesserung des technischen Verständnisses von Herkunft, Transportprozess, Vorkommen und Verhalten von Reifen- und Straßenabriebpartikeln.

Unter Federführung der United Nations Economic Commission for Europe (UNECE) und der International Organization for Standardisation (ISO) sind Referenzprüfverfahren für umwelt- und sicherheitsrelevante Eigenschaften von Reifen entwickelt worden. Sie zielen auf einheitliche und verbindliche Bewertungsgrundlagen für das Verhalten von Reifen, zum Beispiel in Bezug auf Abriebsrate, Geräuschemission, Nasshaftung und Rollwiderstand. Continental hat sich aktiv innerhalb der entsprechenden Fachgruppen der European Tyre and Rim Technical Organisation (ETRTO) hieran beteiligt.

As part of the OLRAP research project (“Online Analysis of Airborne Tire Wear Particles at the Point of Origin and Differentiation from Other Sources”), completed in 2025, Continental, together with the Technical University of Braunschweig, developed an innovative method for analyzing tire wear.

The process uses a specially adapted vacuum device mounted behind a drive wheel. Combined with advanced particle sensors, this method enables the detection of even the finest airborne particles - both behind the wheels and at other points on the vehicle.

The insights gained feed directly into Continental’s tire development, enabling targeted improvements.

More information in our press release.

Our ambition: Increase mileage and reduce wear rate

We are committed to optimizing both the mileage and wear of our tires without compromising safety or performance. Our EcoContact 6 tire line delivers around 20 percent higher mileage and about 30 percent less wear per kilometer compared to its predecessor.

The General German Automobile Club (ADAC) test in 2022 confirmed that the EcoContact 6 has the lowest wear of all summer tires tested (type 185/65 R15) on both dry and wet roads (59 g/1000 km).

The latest ADAC evaluation1 of tire tests from 2023 to 2025 confirms that Continental tires generate 11% less abraded material than the competitor average.

To put this into perspective: a typical mid-size car driving 15,000 kilometers per year produces around 2.25 kilograms of tire wear material with an average tire – but only 1.78 kilograms with Continental tires. That’s a reduction of 470 grams per set of tires².

In the truck segment, the Conti Hybrid Gen3 delivers around 11 percent more mileage and 10 percent less wear per kilometer compared to its predecessor.

1 ADAC: Allgemeiner Deutscher Automobil-Club

2 Simplified calculation based on abrasion values from the ADAC study (mg/km/t) and an assumed vehicle weight of 1.5 tons. The figures are not taken directly from the study but are consistent with the published data.

Regulations

EURO 7 is a new European standard for vehicle emissions that regulates vehicle emissions. The new Euro 7 standard, which will come into force in 2026, also sets limits for brake and tire wear for the first time. The first requirements for tires will come into force in 2028. Similar regulations are expected in the American and Asia-Pacific regions.

Continental’s ambitions:

Through ongoing research and development as well as collaboration with international partners, we are committed to reducing the impact of tire wear particles on the environment, while ensuring that our products meet the highest safety and performance standards.

Related topics

-

2026/02/05Tire NoiseWhat causes tire noise? Find out how Continental is reducing tire noise through innovative solutions.Read more

2026/02/05Tire NoiseWhat causes tire noise? Find out how Continental is reducing tire noise through innovative solutions.Read more -

2026/01/21Tire-related use phase emissionsWhat are tire-relates use phase emissions, and how does Continental reduce them through innovative solutions?Read more

2026/01/21Tire-related use phase emissionsWhat are tire-relates use phase emissions, and how does Continental reduce them through innovative solutions?Read more -

2026/01/21Rolling Resistance of Car TiresLower rolling resistance, greater efficiency: Discover how Continental is minimizing rolling resistance while maximizing safety.Read more

2026/01/21Rolling Resistance of Car TiresLower rolling resistance, greater efficiency: Discover how Continental is minimizing rolling resistance while maximizing safety.Read more