# Conti Bladders

Curing Bladders

General information

Curing is the process of applying pressure to the green tire in a mold in order to give it its final shape, and applying heat energy to stimulate the chemical reaction between the rubber compounds and other materials.

In this process the green tire is automatically transferred onto the lower mold bead seat, a rubber bladder is inserted into the green tire, and the mold closes while the bladder inflates. As the mold closes and is locked the bladder pressure increases so as to make the green tire flow into the mold, taking on the tread pattern and sidewall lettering engraved into the mold. The bladder is filled with a recirculating heat transfer medium, such as steam, hot water, or inert gas. At the end of cure the pressure is bled down, the mold opened, and the tire stripped out of the mold.

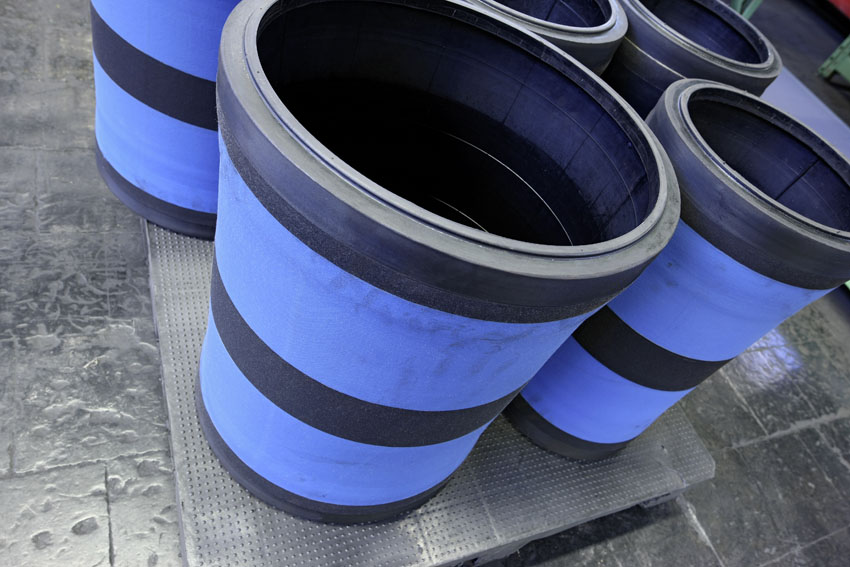

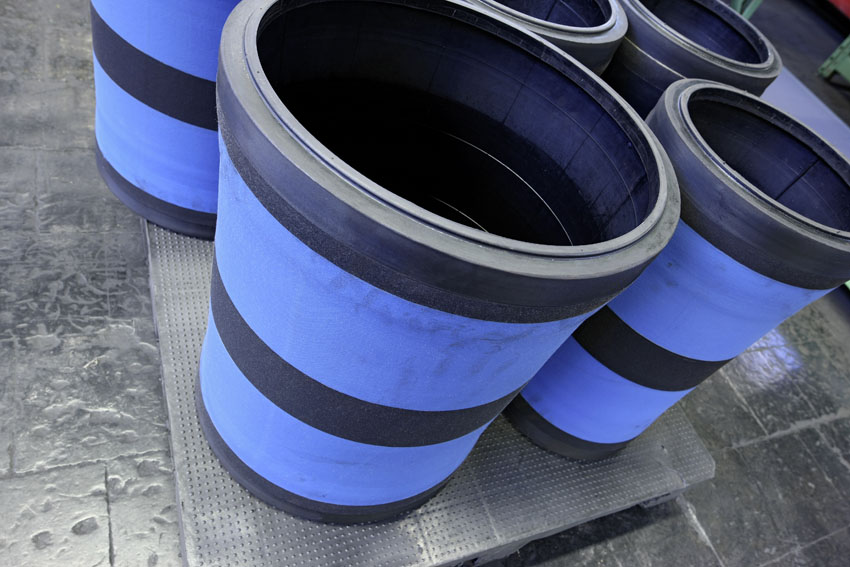

Surface

Our main products have the surface you can see on the right, because of..

..excellent venting to prevent trapped air.

..minimum innerliner consumption.

..the smooth and simple final tire inspection due to constant surface structure. Imperfactions can be easily detected leading to extra ordinary final finish performance.

Recommendations for achieving best Bladder Performance

Continental Bladders are manufactured using a well proven long-lasting heat conductive butyl rubber compound.

The high degree of elasticity of the bladder guarantees trouble-free molding and stripping.

The following points should be considered under all circumstances:

- Bladders should be stored in a dark and dry place, protected from direct sunlight and ozone sources.

- Please follow press manual instructions for proper mounting. Any imperfection of the bladder mounting rings need to be avoided.

- Before mounting bladders into curing press we recommend to pre-treat the bladders with a bladder coating material.

- Before tire curing starts, the bladder should be fully warmed up. For this, the machine should be operated according to the press manual.

- In case of pre-inflating during the warm up, the bladder outside diameter must not exceed the tire sidewall plate outside diameter of the tire mold, in order to avoid non-symmetric deformation.

- If the bladder has cooled down after an interruption in the curing process, it is imperative to warm it up again.

- Heavily oxygenated water should be neutralized by the addition of oxygen scavengers or similar ingredients, in order to avoid deterioration of the bladder.

- To avoid sticking, trapped air or stripping problems a proper application of a tire inside paint is recommended.

To optimize your bladder performance furthermore we recommend the application of a permanent bladder coating material. We can offer you various coating material applied on our bladders.

For our customers, we offer on-site service to optimize bladder application and performance.

In case of any questions please contact your responsible sales representative

-

2026/01/21Tire Building BladdersRead more

2026/01/21Tire Building BladdersRead more -

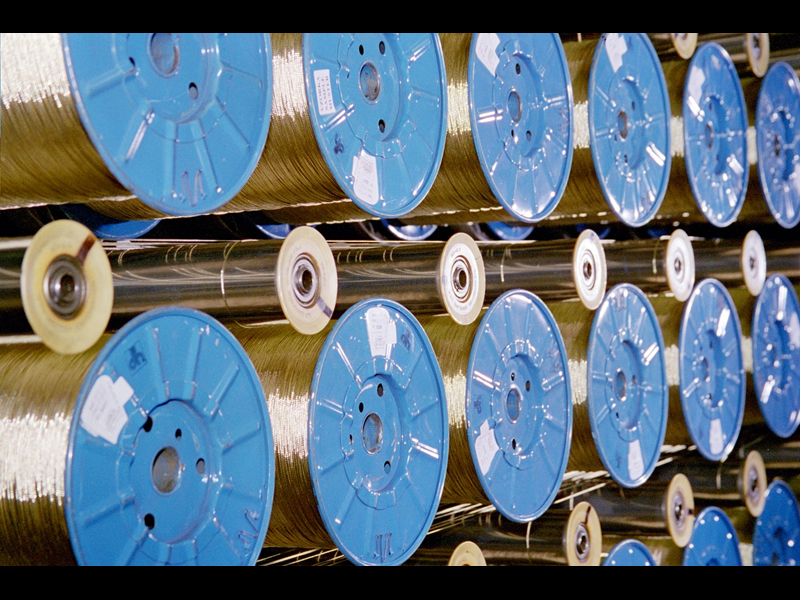

2026/01/21ReinforcementsRead more

2026/01/21ReinforcementsRead more -

2025/04/02DownloadsRead more

2025/04/02DownloadsRead more