Visit Continental Tires in your country for local vehicle fitment

All things run in cycles.

Retreading helps to keep your business running in the most natural way.

Every ending is the beginning of something new. The start of a next round. A fascinating mechanism which gives us an opportunity to think differently about the way we manage our businesses. Retreading tires is a good example of cyclic thinking. And a smart method of reducing costs. At the same time, it contributes to environmentally friendly behavior.

The Enhanced ContiLifeCycle Concept

Our solution for more cost savings, eco-friendliness, and peace of mind.

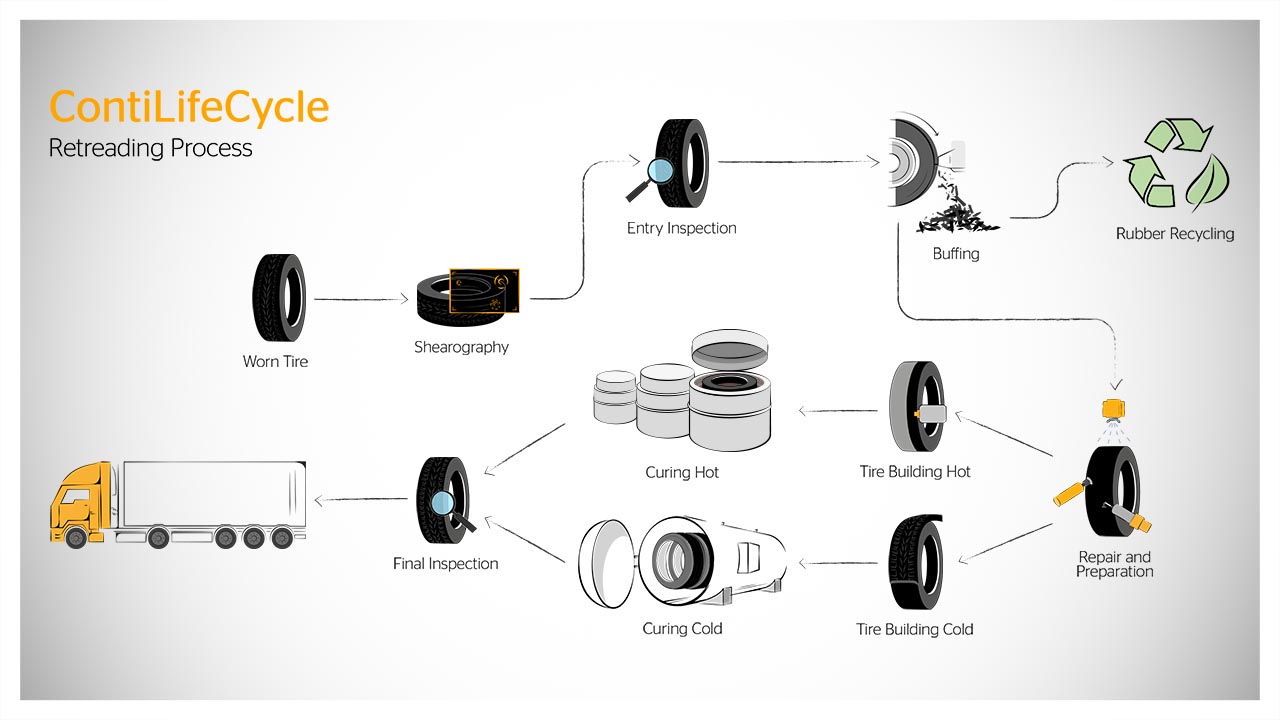

The ContiLifeCycle is a holistic system created to deliver peace of mind to customers by reusing tires and prolonging tire lives. The ContiLifeCycle concept is part of the Conti360° Solutions business, which offers all-round tire management to fleets. There are three steps forming the process, each of them technology-driven.

- New Tires

- Casing Management

- Retreading

In the beginning of the ContiLifeCycle there is the new tire. Designed for ultimate economy, following our cradle-to-grave approach. Made for performance from innovative research and development which we invest in every year. Continental truck and bus tires are long lasting, efficient, retreadable and a cornerstone for optimizing the total cost of ownership of a fleet.

The ContiLifeCycle continues with the Continental casing. With its robust design, our casing is ideal for truck and bus tire retreads. Our casing management provides transparency and flexibility at all times. We take care of your casings from inspection and storage, to purchase and transport, and – if necessary – even to the final disposal.

In the third step of the ContiLifeCycle there are two different options of retreading for your tires: the hot-retreaded ContiRe and the cold-retreaded ContiTread, both of them cost-effective, eco-friendly, and premium quality solutions to prolong Continental tire lives and deliver proven performance and reliability.

High quality at low costs.

Innovative products are the key to set new standards in safety, efficiency, and sustainability. For decades, our engineers have been driven to improve the latest technology to give you clear benefits like lower total costs of ownership.

Your benefits

Peace of Mind

With ContiLifeCycle you can optimize the total costs of ownership of your fleet while enjoying the same advantages a new tire offers.

Safety

Professionally retreaded tires provide a high level of safety. The worn casings have been thoroughly inspected and professionally retreaded with Continental‘s advanced hot or cold retreading solutions. The result is a tire with reliable performance in all key areas.

Premium Quality

Our engineers are constantly improving Continental´s retread solutions. You can rely on premium materials throughout all production and retreading processes.

Investment

Advanced technologies enable us to prolong the life of the tires. Compared to a low-end non-retreadable tire, a retreaded tire enables a lot of benefits. And by using Continental‘s retreading solutions, you can reduce your tire costs by up to 35 percent.

Sustainability

Reusing the carcass reduces the number of old tires in circulation. Retreaded tires help save energy and raw materials and reduce the ecological footprint to protect our environment.

Versatility

The robust and resistant design of our retreaded tires serve all purposes and terrains.

Everything you need to know about retreading

Looks like new, runs like new.

We give every Continental tire multiple lives of robust quality and reliable grip and ensure cost efficiency. Whether your business operates in long-haul transport, construction, or public transport, we make sure you reach every destination efficiently and safely – for the life of the tire and beyond. Therefore, we offer two methods of tire retreading: Hot and cold retreading.

- ContiRe - Hot Retreading

- ContiTread - Cold Retreading

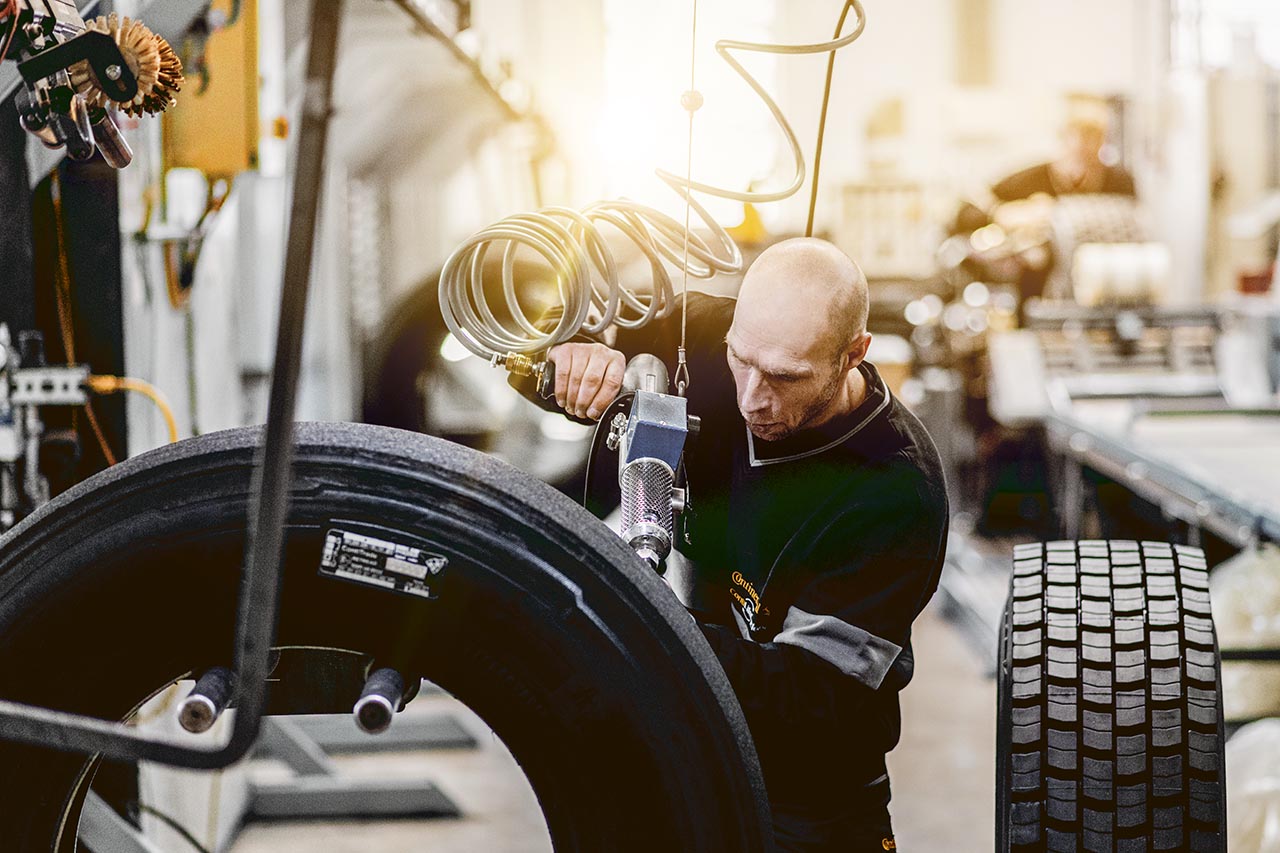

ContiRe tires look and run just like new. Thanks to a hot vulcanization process Continental casings can be renewed from bead to bead. Therefore, a new rubber compound is applied onto the used casing.

To ensure Continental’s high-quality standard, we use the same technologies as in the production of new tires and put every retreaded tire through durability and safety tests.

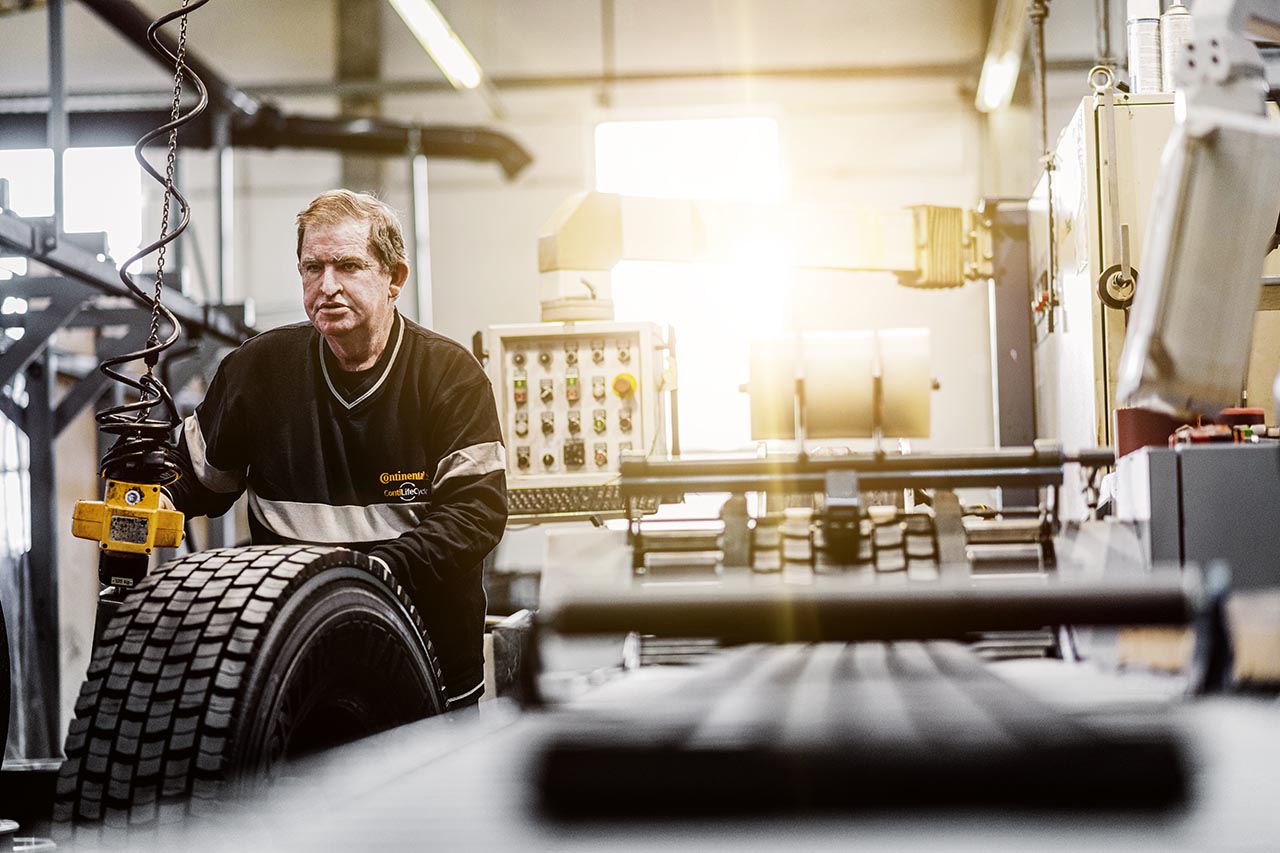

ContiTread extends the service life of your tires. It is the tread that wears down the quickest. So we simply give them a new one using the cold retreading method. Continental’s pre-cured treads utilize the same technologies that we use in the production of new tires.

The solution provides a high level of safety, durability and reliability – so simple, so cool.

Did you know that we offer a retreader portal with important information regarding our ContiTread products?

This is how it works

Our premium retreaded tires

Multiple lives for multiple segments

- ContiRe-Hot Retreading

- ContiTread-Cold Retreading

| Goods | People | ||

| Motorway | ContiRe EcoPlus (HD3/HT3) | Intercity | ContiRe CityPlus (HA3) |

| Regional | ContiRe Hybrid (HD3/HT3+/LD3) | Regional | ContiRe CoachRegio (HD3) ContiRe Coach (HA3) |

| Waste / Recycling | ContiRe CityService (HA3/HD3) | Urban | ContiRe Urban (HA3) |

| Construction | Winter | ||

| On / Off | ContiRe HDC1 ContiRe CrossTrac (HD3/HT3) | Goods | ContiRe Scandinavia (HD3/HT3) ContiRe HDW2/HTW2 |

| People | ContiRe UrbanScandinavia (HD3) ContiRe HSW2 Coach |

| Goods | People | ||

| Motorway | ContiTread HDL2 Eco-Plus | Intercity | ContiTread CityPlus (HA3) |

| Regional | ContiTread Hybrid (HD3/LD3/HT3) ContiTread HTR2 S | Urban | ContiTread Urban (HA3) |

| Construction | Winter | ||

| On / Off | ContiTread HDC1 ContiTread CrossTrac (HD3/HT3) | Goods | ContiTread Scandinavia (HD3/LD3/HT3) ContiTread HDR2 |

| People | ContiTread UrbanScandinavia (HD3) |

Sustainable retreading solutions for a smarter tomorrow.

Retreaded tires are not only an investment in your business. But also an investment in our future. The ContiLifeCycle concept is based on cyclical thinking. It’s a smart way to save emissions for our environment. Retreaded tires replace new ones by reusing valuable components and materials. The casing is what makes our tires so economical and ecological. Due to the high-quality compounds, the reinforcements and the design, the Continental casing delivers an impressive structural durability, that pays off – for the whole service life and beyond.

Compared to a new tire, every retreaded tire saves recources:

Up to

55 kg

of rubbish (rubber, steel and textile).

Up to

85 %

of the materials of a new tire.

Source: Internal tests 2023. Production of the ContiTread HTR2 S 295 3,25 m with the casing 385/65 R22.5 compared to the new tire.