#History #Technologie&Innovation

120 Years of Tread Tires

From the idea to the ideal: A history of tread design

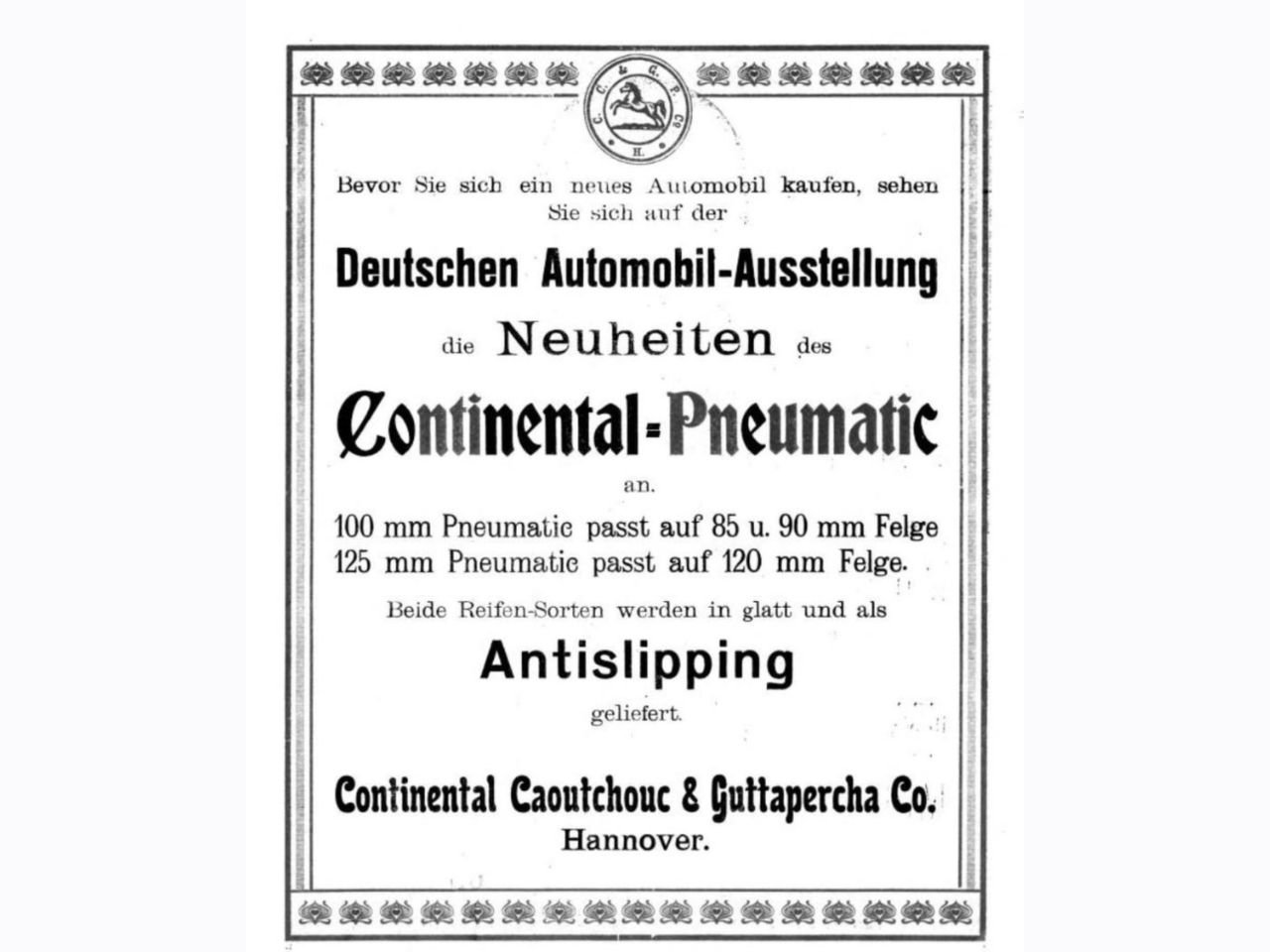

In 1904, Continental set a technical milestone: At the German Motor Show in Frankfurt am Main, the company presented the world's first profiled car tire. What seems obvious today - structured treads for a secure grip - was a revolutionary step for road safety at the time.

The tire was equipped with circumferential, hand-carved grooves that offered considerably more grip on wet and dirty roads. Continental thus laid the foundation for a development that is still characterized by innovative spirit and engineering skill today.

From manual work to digital tire technology

In the 1920s, the demands placed on tires changed fundamentally: roads were paved, and vehicles became faster and heavier. Continental responded with an innovation: tires were no longer smooth and unstructured in their contact surface with the road. Thanks to the new tread pattern with sophisticated block, groove and sipe structures, they offered significantly more grip and driving safety on wet, dirty and snowy surfaces. Continental's tire developers have been improving this principle for more than a century.

Today, tire tread designs are the result of highly complex development processes that make use of artificial intelligence and simulations. Digital prototypes are tested on the computer under realistic conditions long before a tire is physically produced.

More about the technical development of tires:

What the tread does

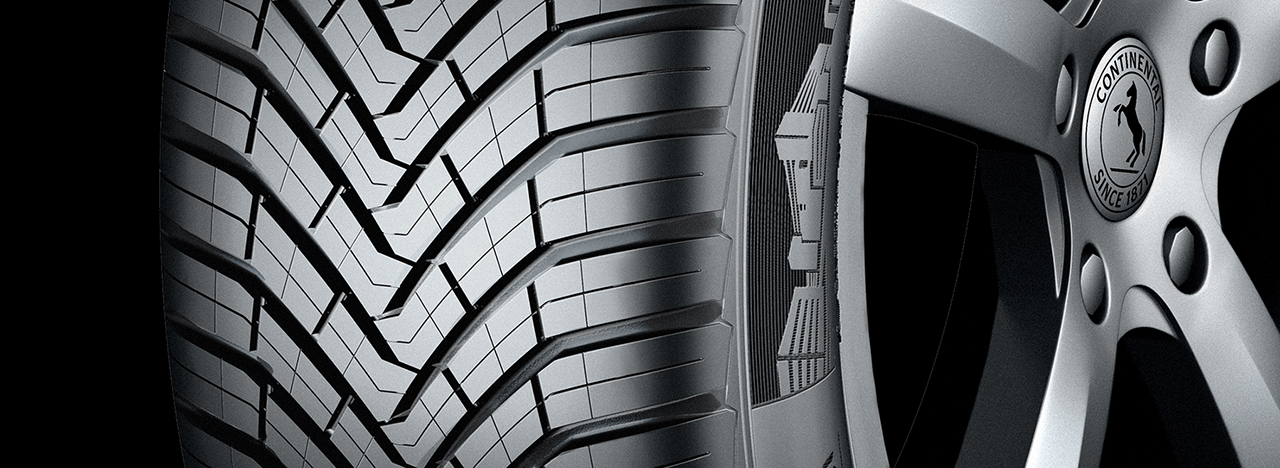

Safety, efficiency and sustainability start with the tread: the tire profile is much more than just a visual feature. It directly influences the performance of a tire - for example when braking on wet roads, in terms of noise development or fuel consumption. The so-called negative portion is particularly decisive: the ratio of the tread grooves to the closed rubber surface. Depending on the intended use - such as summer, winter or all-weather tires - the requirements differ significantly.

The tread fulfills these three central tasks:

- water displacement in wet conditions (aquaplaning protection)

- traction on different surfaces

- mechanical grip in curves and during braking maneuvers

Detailed information on profile types and their functions can be found here:

Current highlights in tire technology

Today, Continental develops suitable tire solutions for almost every requirement - from the highly efficient EcoContact 6 or comfort-oriented PremiumContact to the sporty and dynamic premium tires SportContact 7 and MaxContact MC7 to the robust AllSeasonContact 2 or the cold-resistant VikingContact. The design of a modern tire is the result of countless calculations, tests and fine-tuning - and yet always follows one principle: maximum safety with optimum performance. In addition to performance, environmental aspects are also playing an increasingly important role. In addition to abrasion behavior, tire development also takes into account the energy efficiency and recyclability of the materials used.

Our summer, all-weather and winter tires have different tread structures for their different applications.

Our summer, all-weather and winter tires have different tread structures for their different applications.

A look into the future: intelligent tires and sustainable materials

What began as a hand-carved groove pattern is now a digitally planned high-performance tire with increasingly sustainable raw materials and optimized tread design. Development is not standing still: the continuous improvement of mileage, abrasion rate and rolling resistance without sacrificing safety-relevant properties are important criteria in Continental's tire development. The company's developers also adapt tread designs to changing challenges such as climate change and legal requirements. Optimized tread and special sipe structures for greater fuel efficiency and even greater driving safety will play a key role here.

With over 120 years of experience in tire design, Continental continues to set standards - for safe, efficient and future-oriented mobility worldwide.

More about this topic

-

2026/01/21Continental can look back on a long success story that dates back to 1871. Find out how we became one of the leading tire manufacturers worldwide.HistoryRead more

2026/01/21Continental can look back on a long success story that dates back to 1871. Find out how we became one of the leading tire manufacturers worldwide.HistoryRead more -

2026/02/11At locations around the world, our scientists, designers and engineers work on innovations to make mobility safer, more efficient and more intelligent.Research and DevelopmentRead more

2026/02/11At locations around the world, our scientists, designers and engineers work on innovations to make mobility safer, more efficient and more intelligent.Research and DevelopmentRead more