# Stories

From the Champs-Élysées to your local loop

How Continental brings Tour de France Technology to your everyday ride

From the cobbled climbs of the Tour de France to your favorite weekend loop, Continental road bike tires are built to perform where it matters most. With over a century of expertise and a relentless drive for innovation, we bring pro-level performance to every ride – whether you're chasing a podium or a personal best.

Nowhere is performance tested more fiercely than in the Tour de France – where speed, grip, and durability can make the difference between victory and defeat. At the Tour de France, riders have to perform at their peak – and their equipment has to meet their high standards. That’s where our expertise comes into place: In 2025, Continental-equipped teams claimed an impressive eight stage wins at the Tour de France. Tadej Pogačar, one of the sport’s most dominant figures, made history in 2024 by winning the Giro d’Italia, the Tour de France, and the Road World Championships – all on Continental tires. As Pogačar puts it:

When I choose my tires, I pay close attention to a few important factors that can really influence performance.

Engineering you can feel: Grip, speed, and endurance in every turn

That’s where our advanced tire compounds come in. The professional cycling elite has long relied on our tire technologies, including Tour de France winners like Geraint Thomas (2018), Egan Bernal (2019) and Tadej Pogačar (2024, 2025).

"I've raced on Continental tires for some of the biggest victories of my career. Their tires have been a reliable part of my equipment for the past few years. You can see that they put focus on innovation, safety, and performance and as riders that's exactly what we want to see from our material sponsors."

Tadej Pogačar

All our racing tires have one important element in common: BlackChili. Our patented BlackChili compound has unbeatable grip, speed, and durability. Compared to Activated Silica Compound (our previous performorance compound) BlackChili outperforms in every way:

26%

less rolling resistance

5%

increase in mileage

30%

increased grip

Our innovative Lazer Grip shoulder design is another compound, providing outstanding stability when cornering. The tires forgo a conventional tread pattern in favor of the Grand Prix’s iconic design, offering a large surface area for maximum power transfer. The combination with our precisely tuned Black Chilli compound and innovative design gives riders the perfect balance of speed, control, and safety.

While BlackChili and Lazer Grip deliver speed and grip, protection is just as critical. That’s why we reinforce our Grand Prix 5000 tires with Vectran™, a high-tech fiber originally developed for aerospace applications which is as tough as it is light. Woven into a protective layer beneath the tread, Vectran™ offers exceptional puncture resistance without compromising rolling speed or ride feel. It’s five times stronger than steel by weight, yet flexible enough to maintain the tire’s natural grip and responsiveness. Whether you're racing over cobblestones or dodging debris on your daily ride, Vectran™ acts like a lightweight shield, protecting your tires from punctures.

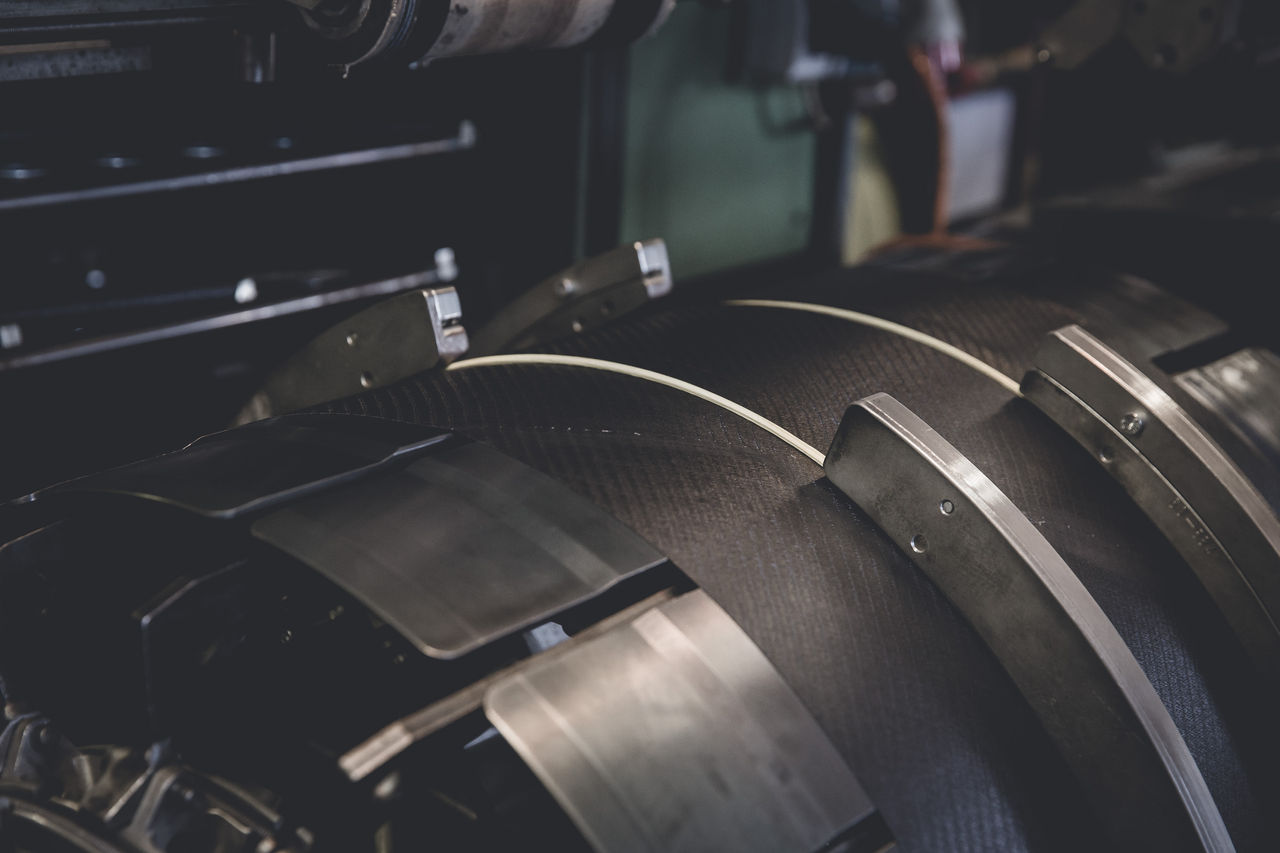

Inside tire production: Where precision meets performance

The continuous development of bicycle tires plays a decisive role in the increasing average speeds in professional cycling. With our high-performance tires, we have made a significant contribution to fact that the average speed at the Tour de France continues to increase every year.

A key factor in this development is the optimization of tire compounds and construction. The same expertise trusted by Tour de France champions is being used to craft tires for your daily ride. From raw compound to finished tire, each stage is carefully engineered to deliver the performance we are known for.

- Korbach

- Produktion 1

- Produktion 2

- Produktion 3

An important part of tire development is the rigorous testing process that all tire models must pass before going into production. For example, tires run against a drum at 50kph continuously for an entire week – the equivalent of 6,000km, a trip from Paris (France) to Dubai. During this process, the tire receives three shocks from various angles with every rotation, the perfect simulation for your average “Tour de France” road surface – or in your local town.

Behind every test, every compound, and every innovation is the simple goal: to benefit from world-class technology. Whether you're racing, training, or just exploring – premiums quality and performance is never to be out of reach.