Benefits of Tyre Monitoring

Increase uptime, decrease costs with tyre monitoring

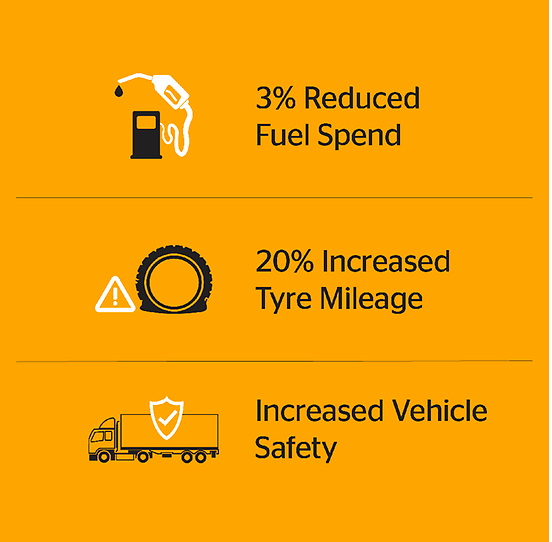

Tyre pressure monitoring systems (TPMS) from Continental deliver operational benefits to your fleet, such as reducing downtime and saving money.

Properly inflated tyres can reduce total tyre-related costs by up to $1,000 per vehicle annually from fuel and mileage costs alone by ensuring proper tyre inflation.

The savings costs above are calculated based on internal benchmark studies.

Actual results may vary.

- Improve Tyre Runout

- Minimize Irregular Tyre Wear

- Save Fuel

- Save Labor & Maintenance Costs

- Reduce Roadside Breakdowns

- Improve Safety

Actual results may vary.

Irregular wear is one of the primary reasons for early tyre removal, and underinflation is often a contributing factor.

Tyres typically lose up to 2 percent of their air pressure every month. Worn valve stems and temperature changes can increase the amount of pressure loss, as can nail holes and other tyre damage from demanding applications such as waste hauling or construction. Proper tyre pressure can significantly extend the tyre’s usable life.

How much do you spend per month on fuel? What would 1% or 2% or 3% savings mean to your bottom line?

Proper tyre inflation increases fuel economy upto 3 percent, versus a tyre that is improperly inflated.

All applications can benefit from fuel economy improvements, because every vehicle has mileage. However, in long haul and regional applications especially, using fuel-efficient tyres at the proper air pressure can deliver significant savings. This is because the vehicles are typically traveling more miles, and also typically traveling at higher speeds. Higher speeds generate more heat, which increases fuel consumption.

Reduce time spent on manual tyre pressure checks and repairing tyre issues caused by underinflation. It can take up to 20 minutes to check the tyre pressure on just one 18-wheeler with a manual gauge!

Manual pressure gauges need to be calibrated frequently in order to maintain their accuracy. The inside dual tyre can be difficult to check, especially if the valve stem is not properly lined up with the outside dual wheel to allow access. Well for thumping a tyre, the less we say the better.

With digital tyre monitoring, the tyre pressure and temperature are already being monitored. Before leaving the fleet yard, drivers can conduct a simple visual inspection to check for tyre wear issues, taking less than half the time.

Many tyre-related roadside breakdowns could be prevented by proper tyre maintenance practices, especially inflation pressure.

All of Continental’s digital tyre monitoring solutions allow your fleet to check tyre pressure before vehicles leave the fleet yard, potentially eliminating a flat tyre call on the side of the road.

ContiConnect also features Slow Leak Detection, an algorithm that can detect a slow leak in a particular tyre over the course of several days, typically before it would be noticed by fleet personnel. Repairing tyres immediately after a puncture or other slow leak is detected can ensure the tyre returns to service, and also protects the tyre for retreading.

Help protect your drivers and other road users.

Improper inflation pressure also changes the tyre contact patch. This affects stopping and acceleration traction and vehicle handling, thereby impacting vehicle safety.

Proper tyre pressure also protects your tyres. As one ContiConnect customer said, “You have a significant investment in rubber on the road, wouldn’t you want to protect it?... If you do it for no other reason, do it for the safety.”