Trusting Continental

The list of criteria for a new car entering the market is endless. Manufacturers have countless aspects to consider, fine-tune, and perfect before their new car can make the desired impact.

One of many decisions they need to make is which tires are best suited. In the end, the decision of which tire manufacturer is to be the car’s original equipment provider is a decision based on trust. Trust in safety, as well as trust in performance capability.

At Continental, building trust with our customers and partners is elementary, and our story as original equipment providers speaks for itself. Time and time again, car manufacturers opt for Continental tires.

Battery electric vehicles: A Continental success story

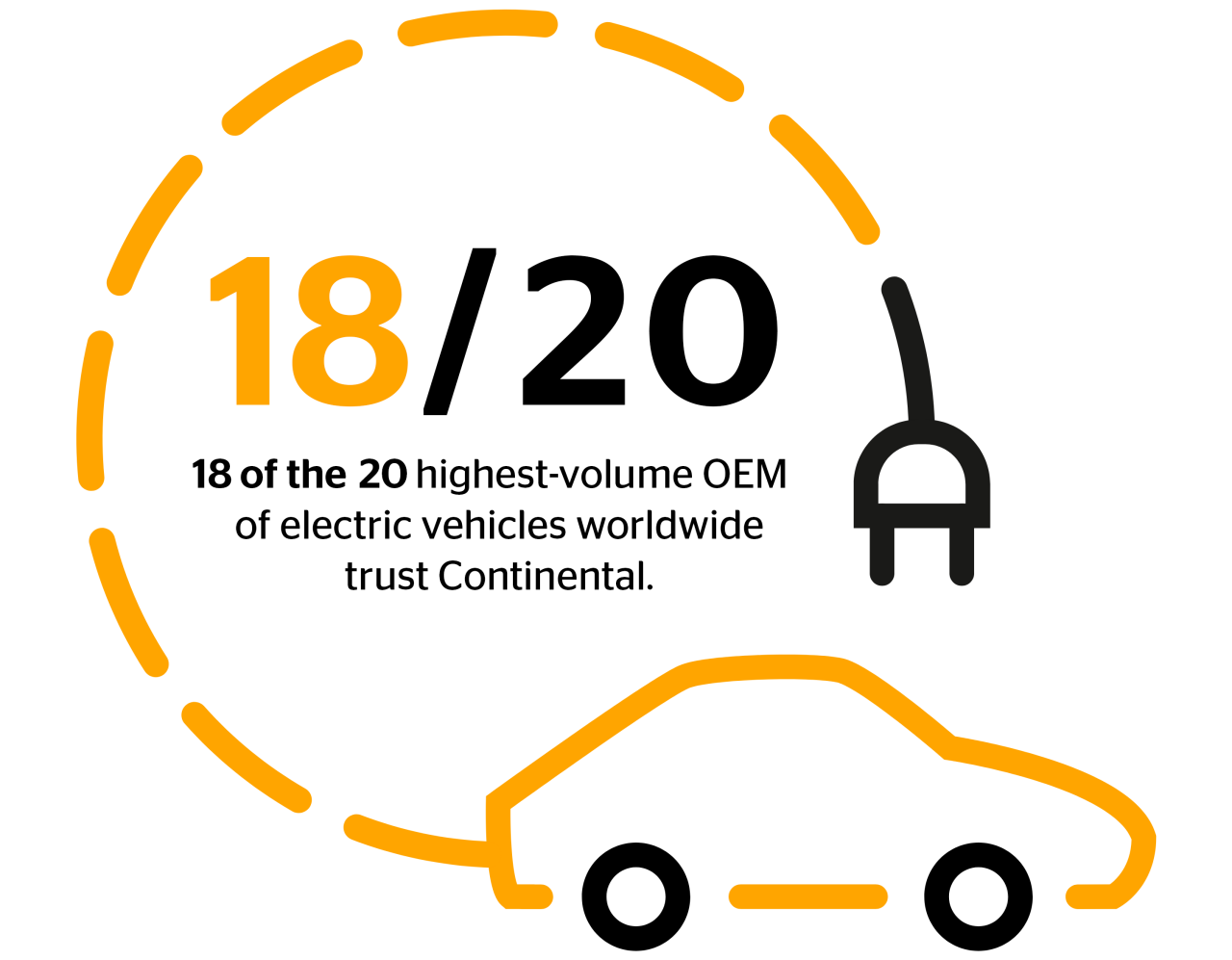

When it comes to battery electric vehicles, the presence of Continental tires as original equipment providers on a global scale is particularly remarkable. Today, 18 of the 20 highest-volume manufacturers of battery electric vehicles worldwide rely on Continental tires.

Our large market share in this area is also constantly rising, which is a testament to our efforts in sustainability topics, underlined, for example, by the fact that every tire in our current product portfolio is compatible for electric vehicles.

Our dedication to sustainability is not going unnoticed by the automotive industry – it has long since become common knowledge among the world’s leading manufacturers that we are proactively contributing to the electromobility trend.

Continental tires - A preferred choice all around

Whatever type of car you drive, there’s a good chance you’re already driving on Continental tires. Car manufacturers in Europe opt for our products in more than 200 models. This makes us a preferred choice of car manufacturers and places us ahead of most of our competitors. No matter the make of your new car, whether you switch from a small car to an SUV, make the switch to an electric vehicle, or finally take delivery of your dream car, the manufacturers know: Continental tires stand for reliable safety.

Getting there was not an easy path: The average development time for a new tire today is around two years. During this time, we develop a tire that is best-suited for the car model and the market where it is released and then subject it to around 100 internal tests. Car buyers ultimately want tires of the highest quality and, above all, highest safety that last as long as possible and let them enjoy their new car for a long time.

3 questions

on OE tire development

Take a look at a modern car and you see a perfectly integrated concept, tires included. The right set of tires ensures that a car’s performance on paper is actually transferred onto the road. Gaining OE supplier approval from automakers indicates the exceptional performance and quality of a product. Given the ever-increasing demands on new car models and the unstoppable technological development, however, developers are facing ever greater challenges, which – to complicate matters – also vary between countries and manufacturers.

What are the key performance characteristics that an automaker expects a tire manufacturer to deliver?

It differs from one country to the next and indeed from one automaker to the next. Generally speaking, the core requirements relate to safety, reducing rolling resistance and increasing sustainability, noise levels in the cabin and exterior noise – all without compromising on safety. The requirements also change over time, especially in current times with the increasing focus on sustainability and electric mobility.

How does Continental ensure that a newly developed OE tire meets the high expectations of car manufacturers?

Today, the development of an OE tire usually begins with a virtual development loop. For example certain characteristics of a tire can be tested on our driving simulator. This is saving valuable resources and time. During the development process, we running countless tests, both virtually and physically on the test track. The goal is to exceed our performance targets, be it for noise generation, handling or rolling resistance. Tests under lab conditions are followed by test drives under real-life conditions on our test tracks. Each team has its own test drivers to handle this task and evaluate if a newly developed tire also works well on the road.

Be part of the world´s largest community

with Continental OE tires

Taking delivery of a new car? Original Equipment tires play an integral role in achieving a comfort and performance capabilities desired for a car, and greatly influences the driver's overall satisfaction with the vehicle. Most importantly, they guarantee safe journeys for you and your family.

Continental in numbers. Top choice for electric vehicles. Nine of the ten highest-volume OEM of electric vehicles worldwide rely on Continental tires.

Continental in numbers. Top choice for electric vehicles. Nine of the ten highest-volume OEM of electric vehicles worldwide rely on Continental tires.

Discover the range

Continental tires

Passenger

Commercial