Visit Continental Tires in your country for local vehicle fitment

# Services and Solutions

Celebrating a decade of excellence

The ContiLifeCycle journey

A tire´s journey beyond the road

In the world of tire manufacturing, Continental has been and enduring pioneer, consistently setting standards for greater sustainability. In the realm of sustainability, let´s quickly touch upon the topic of Circular Economy - where tires become the cool kids on the green block, living by the trio: reuse, recycle and repurpose. And in the tire industry´s adventure, Continental´s ContiLifeCycle steps up as an eco-friendly leader, embodying these prinicples and guiding the industry toward a more sustainable future.

Navigating sustainability: The circular economy unveiled

The circular economy isn't just a buzzword; it's a paradigm shift in how we approach resource management. Instead of the traditional linear model of take, make and dispose, the circular economy advocates a closed-loop system. It promotes the continuous circulation of materials through the stages of reuse, recycling and repurposing. In the context of the tire industry, this means extending the life of tires, minimizing waste and using innovative methods to give new life to existing materials.

The tire industry's rendezvous with sustainability

Tires, often seen as a mere component of a vehicle, play a central role in the broader context of sustainable practices. The tire industry, like many others, is grappling with the environmental footprint of its products. The sheer volume of tires produced globally demands a shift towards more responsible practices. This is where the principles of the circular economy come into play.

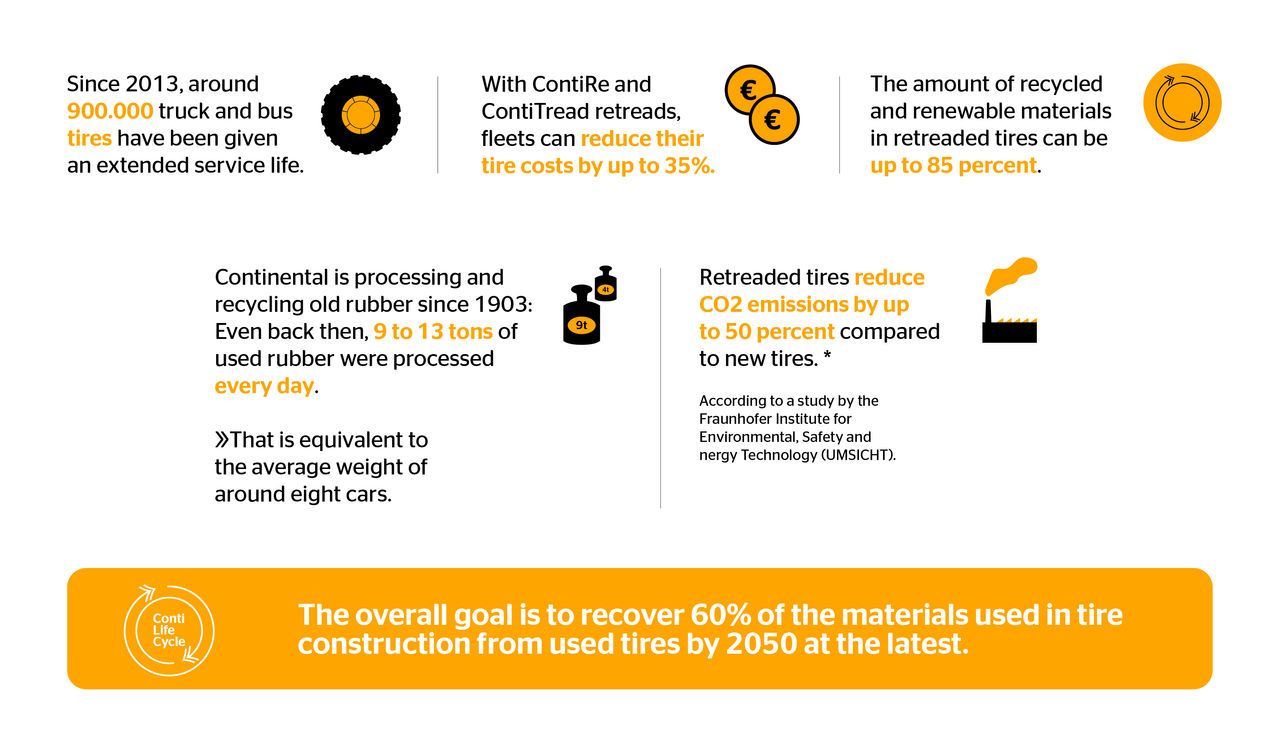

From past to present: A century of circular business practices

On a journey through history, let's retrace the origins of Continental's tire retreading initiatives, which are deeply rooted in the city of Hanover. More than 120 years ago, the Continental plant in Hanover-Vahrenwald pioneered tire retreading, demonstrating an early commitment to sustainable practices. Even then, even in the early 1900s, the roots of circular and sustainable practices were taking shape. In 1903, Continental expanded its footprint by acquiring a factory building in Seelze in the Hanover region. This strategic move led to the creation of a specialised facility focused on the reclamation - the processing and recycling - of waste rubber. Here, old rubber found new life through meticulous processing and recycling, marking a crucial milestone in Continental's sustainable practices. The story hits a high note in 2013 with the emergence of the ContiLifeCycle plant in Hanover-Stöcken. Since then, this plant has been actively involved in the retreading and recycling of more than 900,000 truck and bus tires, giving them a new lease of life.

The ContiLifeCycle: A tire's second act

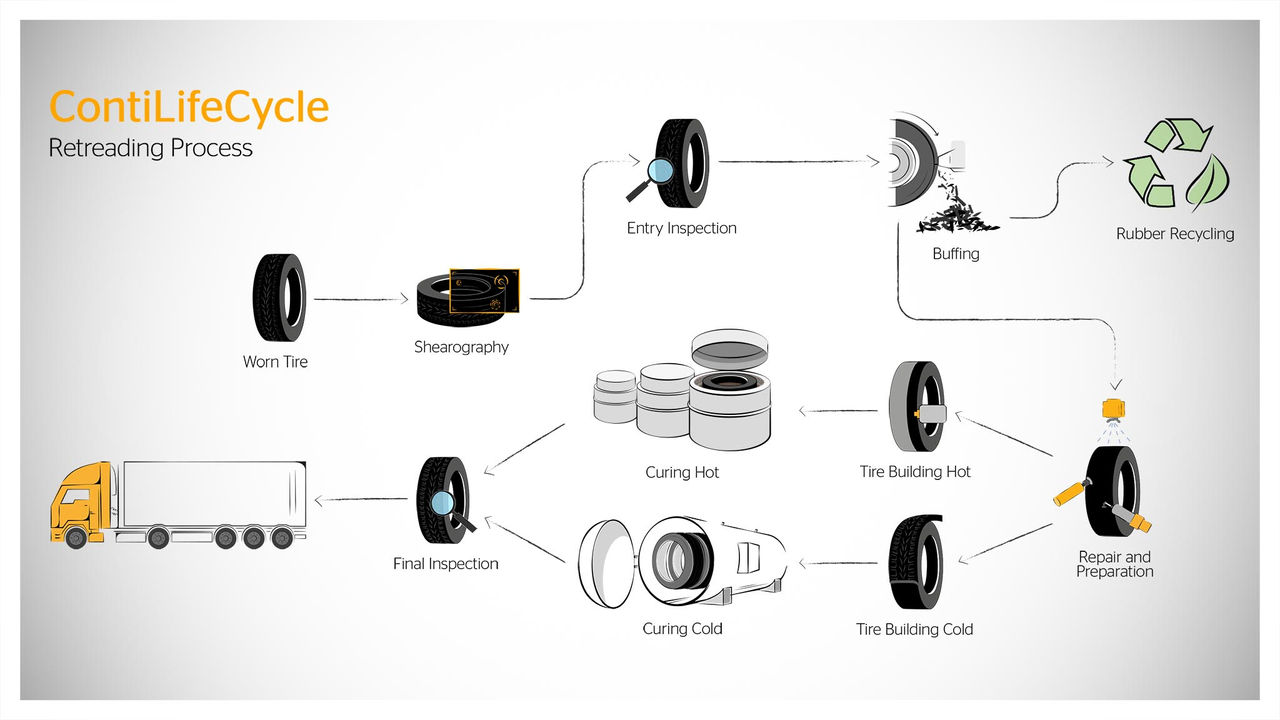

Let’s delve into Continental's ContiLifeCycle a little deeper– not just a solution but a story of transformation. It's a concept that reimagines a tire’s journey, extending it far beyond the road. At its core, ContiLifeCycle is a commitment to reuse, recycle, and repurposing.

Reuse: Through an innovative retreading process, ContiLifeCycle breathes new life into tires that have been worn out on the road. Reusing carcasses conserves valuable resources and extends the life of the tire.

Recycle: The process isn't just about retreading; it extends to comprehensive recycling methods. The ContiLifeCycle plant, with its integrated retreading and recycling facilities, is a testament to the potential of recycling to create a sustainable tire ecosystem.

Repurposing: Beyond the conventional lifespan, ContiLifeCycle envisions tires finding new uses. Whether in the form of innovative materials or as part of other products, repurposing brings the tire's journey full circle.

But it's not just about tires; it's about saving the environment and money.

Added value for fleet customers

The ContiLifeCycle concept goes beyond retreading and contributes to added value for fleet operators. It‘s more than just retreading and actively supports Continental's LODC (Lowest Overall Driving Costs) strategy. Fleet operators experience a significant reduction in tire-related operating costs, with ContiRe and ContiTread retreads delivering up to a 35 percent reduction. This sustainable approach aligns perfectly with Continental's vision of providing robust and fuel-efficient solutions to its valued customers.

Embracing the future of mobility

n the broader story of mobility, ContiLifeCycle is a chapter that resonates with a commitment to a sustainable and circular approach. It's more than just a tire; it's a story of transformation, conservation, and adaptation. As we navigate the waters of the circular economy, Continental's ContiLifeCycle is a testament to what's possible when industry leaders take a broader perspective and make sustainability a journey, not just a destination.

In conclusion, the ContiLifeCycle is not just a historic journey but an ongoing commitment to sustainable and connected mobility. As we reflect on more than 120 years of tire retreading, it's clear that Continental's dedication to innovation and environmental responsibility is driving the future of mobility.

Related articles

-

2023/11/13ContiLifeCycle – Your retread solution of choiceDiscover with ContiLifeCycle our sustainable retread solutions that give new Continental tires multiple lives. Robust, reliable and cost efficient.Read more

2023/11/13ContiLifeCycle – Your retread solution of choiceDiscover with ContiLifeCycle our sustainable retread solutions that give new Continental tires multiple lives. Robust, reliable and cost efficient.Read more -

2025/04/22ContiConnectContiConnect fits your fleet – and your business. Improve your fleet’s performance with our tailored solutions for Digital Tire Management.Read more

2025/04/22ContiConnectContiConnect fits your fleet – and your business. Improve your fleet’s performance with our tailored solutions for Digital Tire Management.Read more -

2024/11/13TireTech AppThe Continental TireTech App is more than just a tire management solution. Access convenient features such as multiple language options, quick tire size conversions, and accurate pressure information.Read more

2024/11/13TireTech AppThe Continental TireTech App is more than just a tire management solution. Access convenient features such as multiple language options, quick tire size conversions, and accurate pressure information.Read more