Rolling Resistance of Car Tires

Tire rolling resistance affects how much energy a vehicle needs to move. That means it directly impacts fuel consumption or range, in the case of electric cars. With the right tire construction and design, rolling resistance can be reduced without compromising grip or safety.

Thanks to Continental’s innovative technologies, you benefit from both low rolling resistance and the highest safety standards – ensuring safe, reliable braking, accelerating and cornering.

What is rolling resistance?

Rolling resistance is the force that opposes a tire’s motion as it rolls, slowing it down. This force is caused by the deformation of the tire as it makes contact with the road. Rolling resistance is proportional to the normal force acting on the tire and is determined by the rolling resistance coefficient. This coefficient represents the mechanical energy lost by a rolling tire, which is converted into heat over the distance traveled. Factors such as the composition of the tread compound, hysteresis, tire construction and tire pressure all influence rolling resistance – as well as the overall lifespan of the tire.

What is hysteresis?

A simple example for hysteresis is a sponge. When you squeeze it and then let go, it takes a moment to return to its original shape. This delay is called hysteresis. It means that a material or system does not respond immediately or fully to a change, but with a certain delay and often only partially. In a tire, hysteresis describes the delay with which the tire returns to its original shape after being deformed. This delay leads to energy loss, which increases rolling resistance and, in turn, a vehicle’s fuel consumption or range.

What are the effects of rolling resistance?

Higher rolling resistance means more energy is needed to keep a vehicle moving. This leads to greater energy consumption, reduced range and ultimately higher costs.

But rolling resistance is not all bad. In fact, a certain amount is essential for road safety. That is because part of the resistance caused by friction between the tire and the road surface generates traction, also known as grip.

Grip is what keeps your vehicle stable when accelerating, braking or cornering and is key to maintaining control on the road. However, this grip also causes energy loss in the form of heat, which increases rolling resistance. So the challenge is finding the right balance: can a tire offer both low rolling resistance and good grip? Continental is continuously working to optimize this balance, developing tires that are both energy efficient and safe.

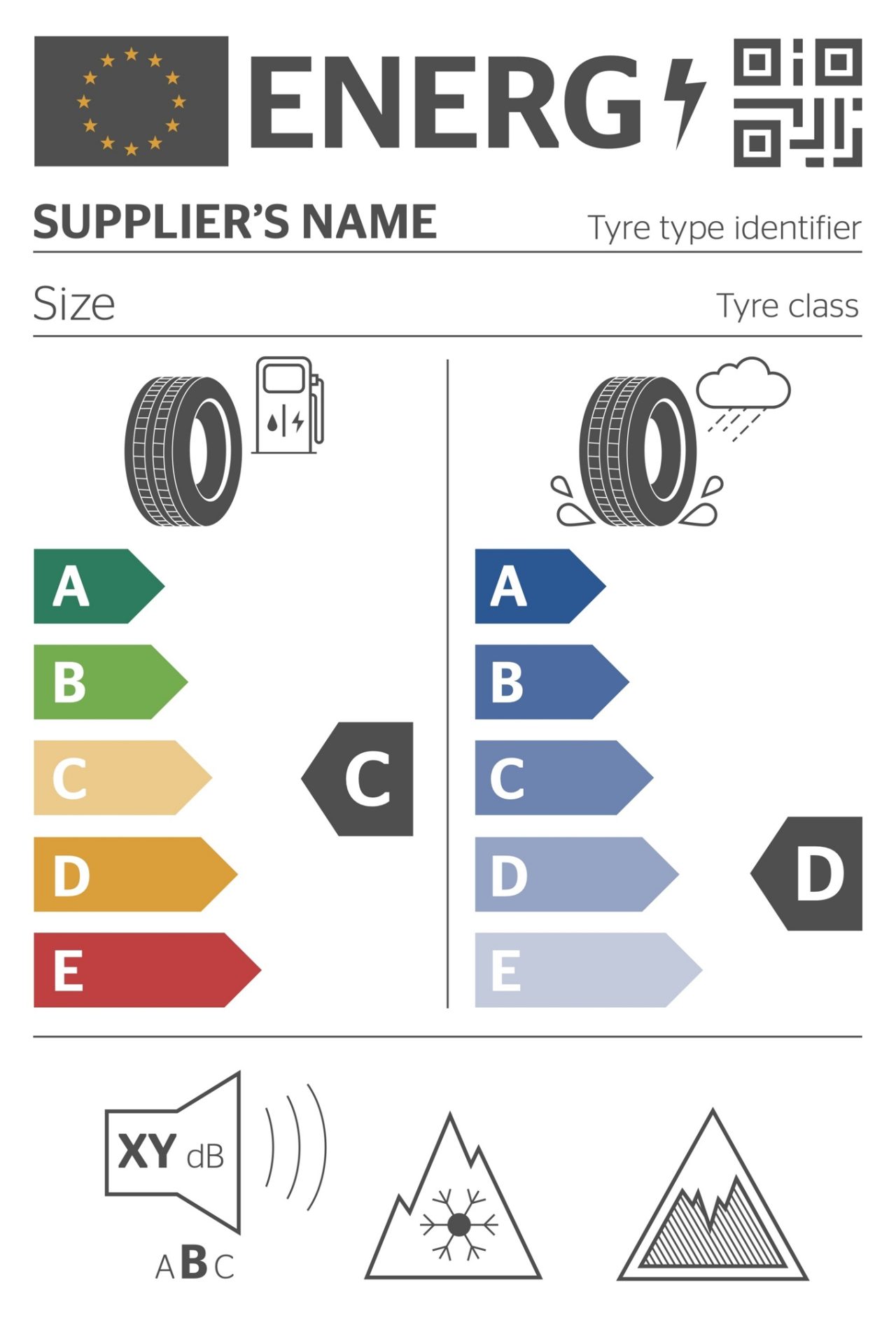

EU tire label: understanding rolling resistance

Under EU regulations, all tires must come with a label – either as a sticker on the tread or as a printed label included with the product.

This label provides key performance information, including the tire’s rolling resistance, which directly affects fuel consumption. Rolling resistance is rated in five classes, from A to E. The lower the resistance, the less fuel your vehicle consumes.

For example, an A-rated tire can save around 0.5 liters of fuel per 100 kilometers compared with an E-rated tire – roughly a 7.5 percent improvement in efficiency. Since most tires belong to classes B or C, the actual fuel savings are typically lower than the theoretical maximum of 7.5 percent.

The table below shows the different rolling resistance classes. According to the General German Automobile Club (ADAC), each step down in class results in the following increase in fuel consumption:

| Efficiency/rolling resistance class | Additional fuel consumption in liters/100 km |

|---|---|

| A | No additional fuel consumption |

| B | + 0.1 liters |

| C | + 0.22 liters |

| D | + 0.36 liters |

| E | +0.51 liters |

Source: ADAC

This labeling system helps consumers choose more environmentally friendly and fuel-efficient tires. Similar regulations also exist in other countries and regions:

- South Korea has had mandatory tire labels since 2012. Rolling resistance is rated as fuel efficiency on a scale from A to E, encouraging the use of low-resistance tires to reduce fuel consumption.

- Japan introduced a voluntary tire labeling system in 2010.

- The Gulf Standardization Organization (GSO) – which includes Bahrain, Yemen, Qatar, Kuwait, Oman, Saudi Arabia and the United Arab Emirates – has mandated tire labeling since 2016. Its system classifies rolling resistance into six categories, from A to F.

- Brazil also enforces mandatory tire labeling, including both rolling resistance and wet grip performance.

In many other countries, however, rolling resistance is not yet indicated through a standardized label.

What affects rolling resistance?

Tread pattern

The design of the tread does not significantly affect rolling resistance. Only tires with deep, defined tread patterns, such as winter or off-road tires, typically have higher rolling resistance than those with smoother profiles. That said, deeper treads provide more traction on snowy, icy, muddy or off-road terrain.

Tire pressure

The correct tire pressure is crucial for minimizing rolling resistance. If the pressure is too low, the tire deforms more, causing greater energy loss and increased resistance. Too much pressure can lower rolling resistance but reduce ride comfort and grip. So it is important to maintain the recommended tire pressure and check it regularly.

Tire width

Wider tires have a larger contact area with the road, which increases grip – but this has no direct effect on rolling resistance compared with narrower tires.

Rubber compound

The rubber compound plays a major role in rolling resistance. Tires need different properties depending on the season. During colder months, softer compounds provide better grip on slippery, icy or snow-covered roads. In summer, warmer conditions require compounds that offer optimal grip on both wet and dry surfaces. Generally, summer tires have lower rolling resistance than winter tires. However, the hardness of the tire does not directly impact rolling resistance.

What are low rolling resistance tires?

Low rolling resistance (LRR) tires are designed to minimize the energy lost as they roll, lowering fuel consumption and increasing range.

Continentals is to keep reducing rolling resistance across all its tires – from passenger cars to commercial vehicles – to help lower fuel consumption and CO2 emissions and to extend the range of electric vehicles. That is why rolling resistance is a key factor throughout Continental’s tire development process.

Thanks to innovative tread patterns, advanced rubber compounds and cutting-edge engineering, Continental produces high-quality tires that combine low rolling resistance with excellent grip, safety and performance. Safety remains Continental’s top priority, as confirmed by numerous independent tests: Tests and test results

How is Continental tackling rolling resistance?

Continental uses innovative technologies and materials to minimize rolling resistance while maximizing tire safety and performance. Through specialized rubber compounds, correct tire pressure and refined tread patterns, we are able to reduce rolling resistance without compromising grip or tire longevity.

In the mid-1990s, Continental was one of the first tire manufacturers to revolutionize driving safety and energy efficiency by using silica as a filler in tread compounds. This breakthrough shortened braking distances by nearly 50 percent compared with previous standards and significantly reduced rolling resistance. Today, our experts continue to research and develop new silica-based compounds to improve the energy efficiency of tires even further. We are also committed to making silica production more sustainable. We already use an eco-friendly form of silica made from rice husk ash – a byproduct of rice production that cannot be used for food or animal feed. Producing silica from rice husk ash is more energy efficient than traditional methods using quartz sand.

Selected Continental tires with low rolling resistance

- EcoContact 7

- UltraContact NXT

- Conti EfficientPro 5

EcoContact 7

A prime example of our commitment to energy-efficient tire design is the EcoContact 7. This tire combines exceptionally low rolling resistance – making it highly efficient – with quiet rolling noise and excellent handling. These qualities make the EcoContact 7 an ideal choice for electric vehicles as well. Another highlight is the PremiumContact 7, which also delivers low rolling resistance thanks to its innovative tread design and advanced material composition – while meeting the highest safety standards and offering superior driving comfort. In the commercial sector, the Conti EfficientPro 5 sets new benchmarks for energy efficiency as an original equipment tire designed for long-haul applications.

As part of a customer project, Continental has also developed an original-equipment version of the EcoContact tire that exceeds the EU tire label’s top energy efficiency rating (class A) by around 17 percent – making it especially low in rolling resistance. This improvement was achieved through a redesigned tire sidewall and a specially formulated tread compound.

Find out more about the EcoContact 7 and EcoContact 7 S

Ultra Contact NXT

The UltraContact NXT is our most sustainable production tire to date for passenger cars. Comprising up to 65 percent renewable, recycled and mass balance-certified materials, it combines sustainability with maximum safety and performance. All 19 sizes have achieved top EU tire label rating (A) for rolling resistance, wet braking and exterior noise.

Find out more about the UltraContact NXT

Conti EfficientPro 5

The Conti EfficientPro 5 is designed for trucks with internal combustion engines, hybrid systems or fully electric drives. Our engineers have reduced its rolling resistance by 10 percent compared with its predecessor – while maintaining its top-tier class A EU label rating. As a steering-axle tire, it is also the first long-haul tire in size 315/70 to support an axle load of 8.5 metric tons, making it ideal for electric trucks. This original-equipment tire sets new standards for energy efficiency in long-distance transport and helps extend battery range in electric commercial vehicles.

Its special tread compound and stiff tread design contribute to both lower rolling resistance and higher mileage – around 5 percent more than the previous model. The tread also delivers reliable grip and excellent directional stability. With its exceptionally low external rolling noise (EU tire label class A), the Conti EfficientPro 5 is also EU Taxonomy-eligible.

Find out more about the Conti EfficientPro 5

Continental’s ambitions

At Continental, low rolling resistance, quiet rolling noise and long tread life are at the heart of tire development.

We are committed to making its tires more energy efficient and environmentally friendly – from their production and everyday use to their recyclability. As a premium tire manufacturer, we continually invest in the research and development of innovative technologies, alternative materials and sustainable production processes.

Related Topics

-

2026/01/29Tire and Road Wear ParticlesTire wear is necessary for safe driving. Optimal traction and reduced wear with Continental.Read more

2026/01/29Tire and Road Wear ParticlesTire wear is necessary for safe driving. Optimal traction and reduced wear with Continental.Read more -

2026/01/21Tire-related use phase emissionsWhat are tire-relates use phase emissions, and how does Continental reduce them through innovative solutions?Read more

2026/01/21Tire-related use phase emissionsWhat are tire-relates use phase emissions, and how does Continental reduce them through innovative solutions?Read more -

2026/02/05Tire NoiseWhat causes tire noise? Find out how Continental is reducing tire noise through innovative solutions.Read more

2026/02/05Tire NoiseWhat causes tire noise? Find out how Continental is reducing tire noise through innovative solutions.Read more