Proven tread designs. Optimized compounding. Best-in-class process.

Continental Retread Solutions offers a comprehensive approach to optimizing your fleet's performance and sustainability. Combining our durable 3G tire casing technology and application-specfic ContiTread tread designs, our retreads help lower your fleet's overall driving cost and maximize productivity.

Whether you're retreading truck, bus, or trailer tires, trust Continental to deliver the highest quality retreads that will keep your fleet running smoothly and efficiently.

- The New Standard in Premium Retreading

- Delivering Retreading Innovations

- Towards a More Sustainable Future

- Retread Partner Network

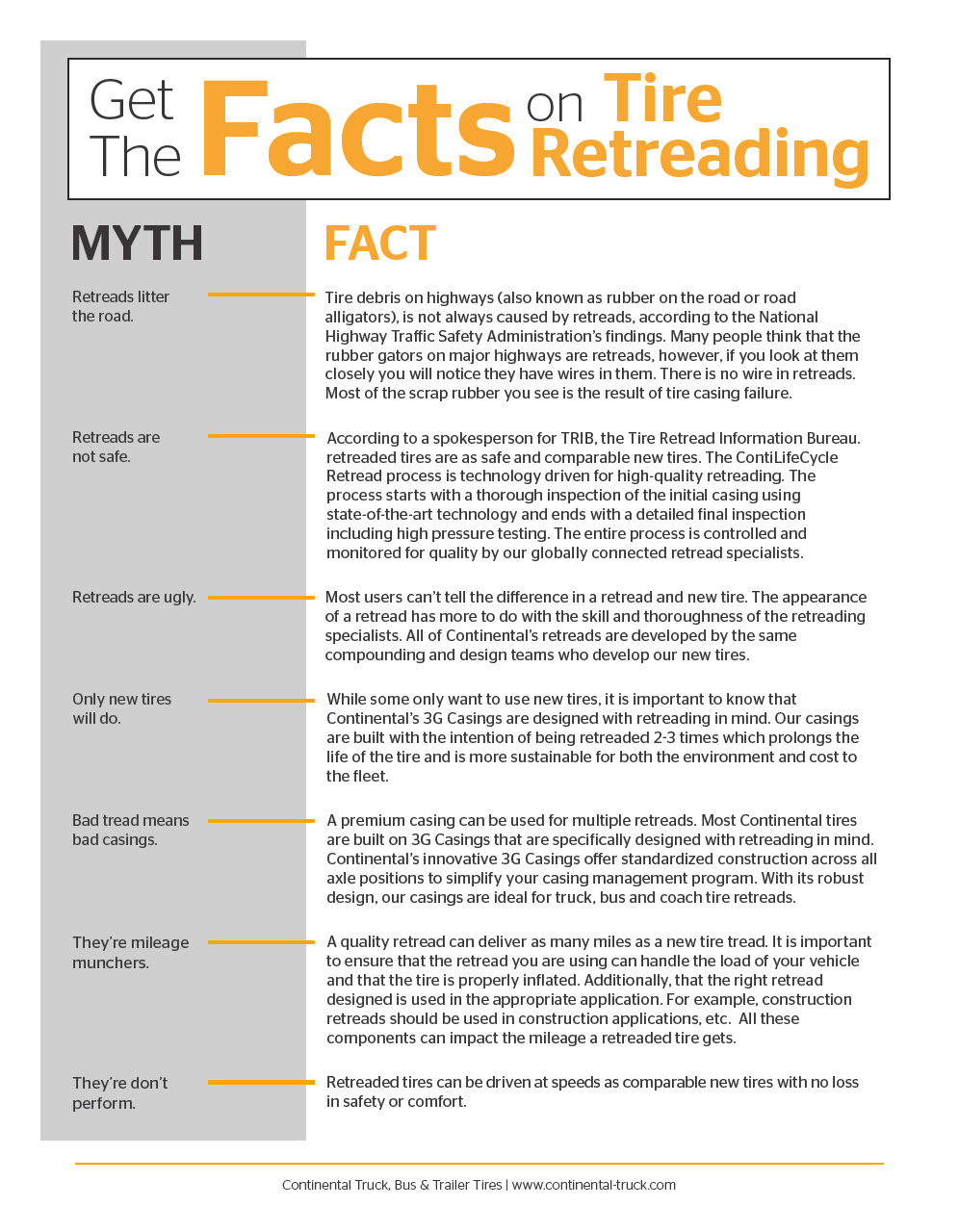

The Benefits of Retreading

Why retreading is a smart choice

Profitability

Reduce total costs by retreading your tires with ContiTread retreads. Our proven solutions offers fleets nearly 30% in savings compared to a new tire, while improving fuel efficiency and overall performance.

Extended Tire Life

Maximize the total value of your casings with confidence using our ContiLifeCycle retread process. Our durable 3G casings can be retreaded multiple times and last longer than low-cost new tire alternatives.

Fuel Efficiency

Reduce fuel costs by 3% to 5% and cut emissions with our range of SmartWay verified tread options designed to improve rolling resistance without sacrificing mileage.

Safety & Reliability

Our premium ContiTread retreads are built and inspected with the same rigorous standards as new tires. They offer exceptional durability, mileage, and peace of mind on the road.

Sustainability

By extending the tire’s lifespan, retreads cut CO2 emissions by 24%, reduce landfill waste by 1.4 billion pounds, save 217.5 million gallons of oil, and use 29% less land, offering significant environmental benefits.

Why Choose Continental?

Fuel-Efficient Retreads

Continental offers over 30 retread patterns including low-rolling resistance and SmartWay Verified options. Our fuel efficient ContiTread patterns provide a cost-effective solution that can reduce transportation-related emissions and improve fuel economy by +3%. Search SmartWay retreads

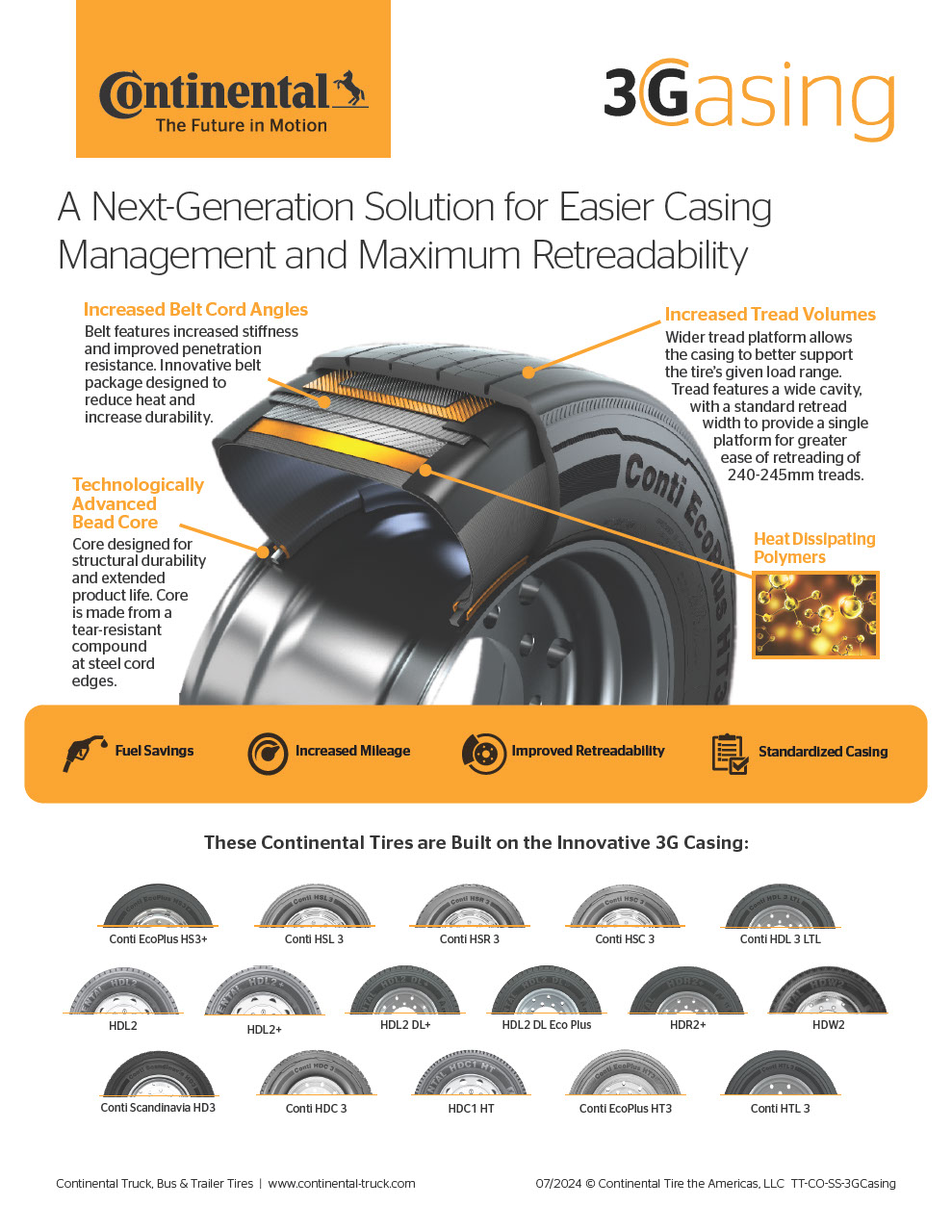

Maximum Casing Retreadability

Our innovative casing is ideal if you plan to retread your truck and bus tires as part of our ContiLifeCycle™ solution. 3G Casings include special design features to improve performance like a wider tread platform, increased belt cord angles and heat dissipating polymers to protect them. Learn about 3G Casings

One Tire, Multiple Lives

Retreading is not only an investment for your business, but for the future as well. The ContiLifeCycle concept is based on cyclical thinking. Our process is designed to extend your tire's lifespan through multiple retreads, a cost-effective way to increase profitability and reduce environmental impact. Check it out

An Integrated Solutions Provider Approach

As a reliable fleet partner, we offer fully integrated tire solutions that consider the entire lifespan of your tires to lower your overall driving cost. Retreading is a vital component to help reach your efficiency goals.

Have a question?

Don't hesitate to contact us if you would like more information on Continental's Retread Solutions or require specific support.